1.Overview

CTI9N(W)- I type spring-operated mechanism is based on the original CT19 type

spring-operated mechanism for 40.5kV vacuum circuit breaker, to strengthen, improve and

perfect, its mechanical strength, stability and reliability have been greatly improved. CT19W

type can be used to operate all kinds of outdoor 40.5kV capacitance circuit breaker. CT19N

type can be used to operate all kinds of indoor 40.5kV vacuum circuit breaker, its

performance meets the requirements of GBI984 "AC high voltage circuit breaker" and the

"technical conditions" of this product, each index meets and exceeds the "IEC" standard

mechanism closing spring storage. Vacuum circuit breaker, its performance in line with the

GBI984 "AC high-voltage circuit breaker" and the product "technical conditions"

requirements, the indicators have reached and exceeded the "EC" standard mechanism

closing spring energy storage mode has two kinds of electric energy storage and manual

energy storage; split gate operation has a split gate solenoid and manual push-button

operation of the two kinds of

Organization of the specifications and matching of the main components such as Table l.

|

Specification |

Weight(kg) |

Dimensions |

Input power |

Closing |

Opening current |

|

HxWxD(mm) |

(W) |

spring(mm) |

(kA) |

||

|

CT19N-I |

45 |

440x325x177 |

160 |

Ф10+Ф6 |

20-31.5 |

|

CT19W-I |

45 |

550x325x177 |

160 |

Ф10+Ф6 |

20-31.5 |

2 Use of environmental conditions

a, the upper limit of ambient temperature +40 ℃, and the average value measured within 24h does not exceed 35 ℃, the lower limit of -15 ℃ b. Altitude not exceeding 3000m.

e. Relative humidity: the average daily value does not exceed 95%, the average monthly value does not exceed 90

d, water vapor pressure:daily average value does not exceed 2.2kPa, monthly average value does not exceed 1.8kP:.

e.The surrounding air is not obviously polluted by dust, smoke, corrosive or combustible gases, vapors and salt spray,

In more than GB / T11022-1999 provisions of the above normal environment and other conditions of use, the household can be negotiated with the manufacturer to solve the problem.

3 Closing mode

3.1 The organization also has a manual button and electric (solenoid) closing operation; 3.2 The organization also has a manual button and electric (solenoid) closing operation.

3.2 The organization has both manual button and independent power supply electric (solenoid) breaking operation;

3.3 The organization has over-current release tripping and under-voltage release tripping function.

3.4 The organization has the function of manual slow opening and closing operation (when debugging with the circuit breaker).

4 Technical parameters

4.1 Energy storage motor adopts single-phase permanent compensation self-current motor, its technical parameters such as Table 2.

|

Table 2 |

||

|

Specifiation |

66ZY-CJ22 |

|

|

Rated working voltage(V) |

||

|

Rated motor output power(W) |

160 |

|

|

Normal working voltage range |

85%-110% of rated operating voltage |

|

|

Rated working voltage storage time(n) |

≤14 |

4.2 Manual energy storage operation, when using 500mm long energy storage operating handle, its operating force is not more than 300N.

4.3 The closing solenoid adopts screw tube type solenoid, and its technical parameters are shown in Table 3.

Table 3

|

Rated working |

voltage(V) |

AC/DC 110 |

AC 220 |

DC 220 |

|

Rated working |

current(A) |

1.5 |

1.5 |

1.2 |

|

Rated power (W) |

165 |

330 |

268 |

|

|

Coil resistance value at 20℃(Ω) |

71±2 |

71±2 |

180±2 |

|

|

Normal Operating Voltage Range |

85%-110% (AC) or 80%-110% (DC) Rated voltage |

|||

|

4.4 Tube-type |

solenoid is used for tripping solenoid and overcurrent striker solenoid powered by |

|||

independent power supply.

![]()

4.4.1 Current stripping solenoid (No.1 striker) is powered by current transformer, and its circuit relies on the overcurrent relay installed in the contact action closure, and the action value is rectified by the overcurrent relay.

![]()

4.4.2 The tripping solenoid (No. 4 striker) powered by an independent power supply, its technical parameters are shown in Table 4.

Table 4

|

Rated working |

voltage(V) |

AC/DC 110 |

AC 220 |

DC 220 |

|

Rated working |

current(A) |

2.0 |

1.5 |

1.9 |

|

Rated power (W) |

220 |

330 |

418 |

|

|

Coil resistance value at 20℃(Ω) |

54±1 |

71±2 |

115±2 |

|

|

Normal Operating Voltage Range |

85%-110% (AC) or 80%-110% (DC) Rated voltage |

|||

Note:

Other combinations of detent should be determined by the user in consultation with the manufacturer.

3.5 Others

3.5.1 The working angle of the output shaft of the mechanism is 50~55 degrees.

3.5.2 The net weight of the mechanism is 45 kg.

4.5.3 Mechanisms with 40.5kV outdoor and indoor high-voltage vacuum circuit breaker operating time.

a. Closing time not more than 0.15 seconds.

b, the inherent breaking time is not greater than 0.06 seconds:.

c, primary automatic reclosing no current gap time is not greater than 0.30 seconds.

4.5.4 Select F10 auxiliary switch, a total of 6 pairs of normally open contacts, 6 pairs of normally closed contacts, contacts can pass the continuous current in the AC220V for 10A, in the DC220V for 3A.

4.5.5 Select CSK-22 type magnetic blowing switch, there are two pairs of normally closed contacts, two pairs of normally open contacts, contacts can pass the continuous current in the AC220V for 10A, DC220V for 3A.

4.5.6 Selected TS-212A type terminals, a total of 3 with 36 sections of terminals, terminals can pass the continuous current of I0A.

5 structure and action principle

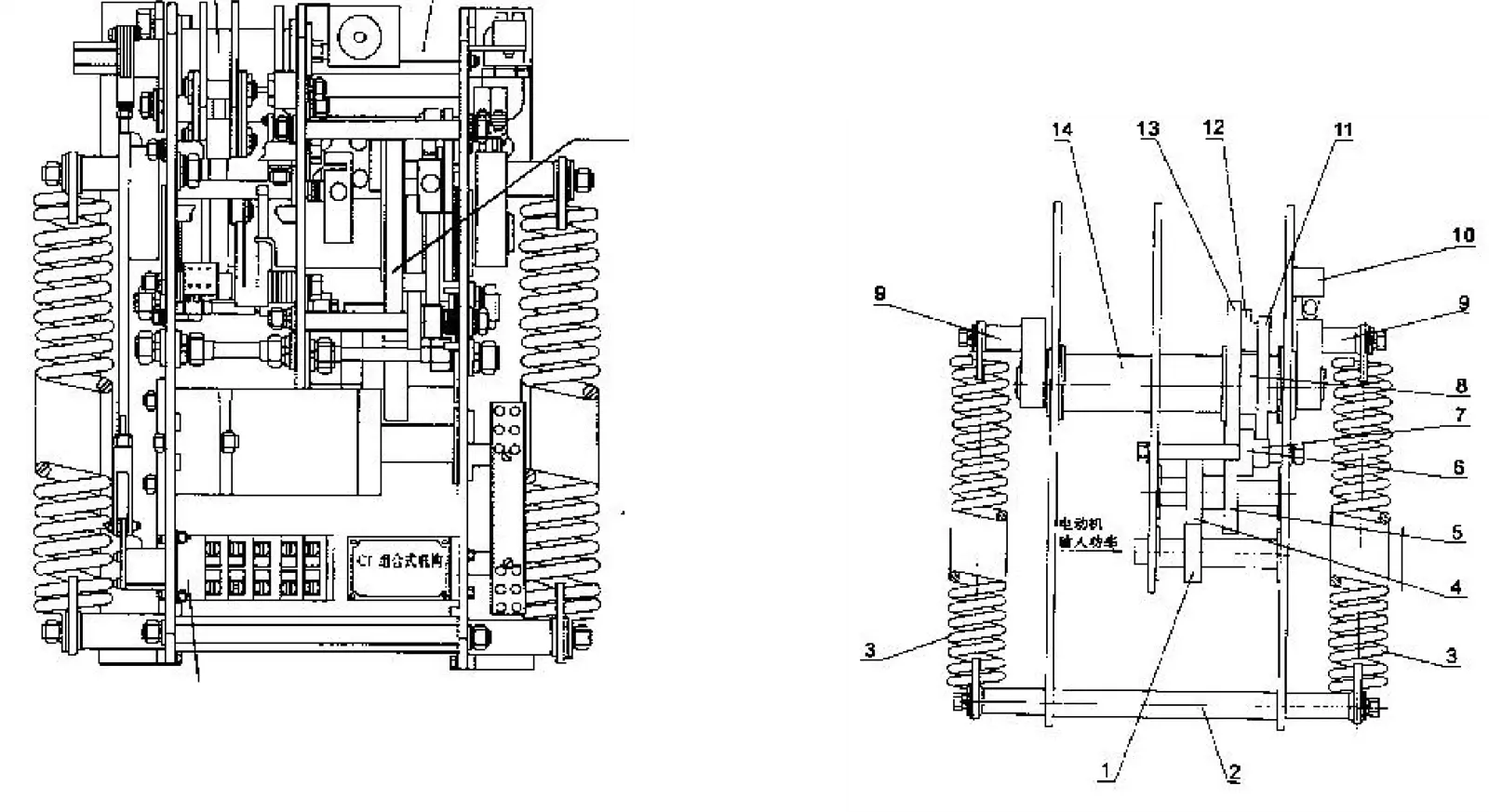

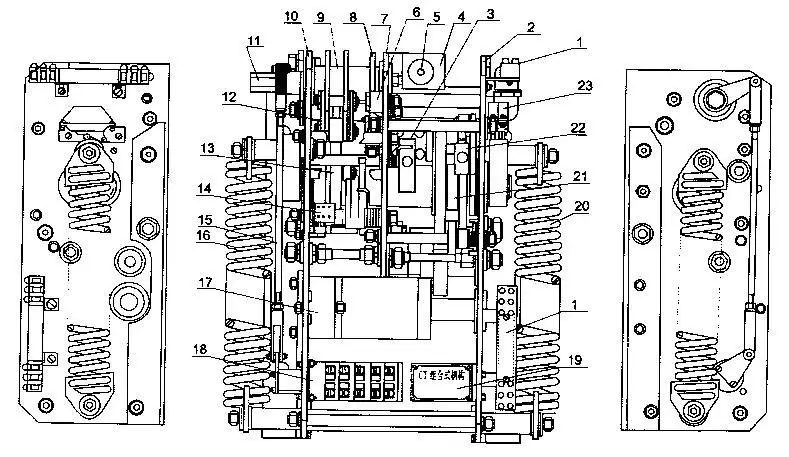

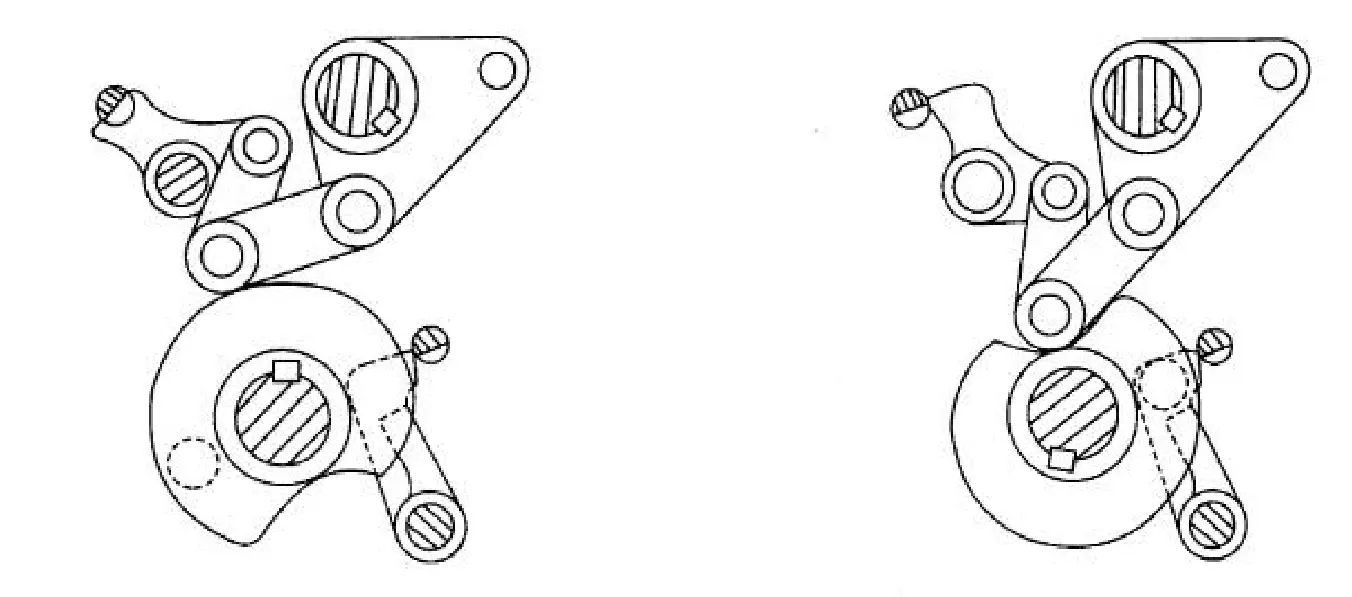

5.1 Fig. 1 and Fig. 3 for the CT19N type spring-operated mechanism of the structural sketch, Fig. 4 for the CT19W type spring-operated mechanism of the structural sketch, they have a combination of the overall layout of the structure of the organization of the various functional units are relatively independent at the same time and has a simple and beautiful appearance.

5.2 The mechanism is mainly composed of four units, namely, driving unit, energy storage unit, disconnector unit and electrical control unit.

The driving unit is located between the left side plate and the middle partition plate, which is a cam-link type mechanism matching the movement and load characteristics of the vacuum circuit breaker, and its components have reasonable force, stable and reliable action, good shock resistance, and its output shaft is located at the top end of the mechanism, which has an open structure and is easy to be mated with the circuit breaker.

The energy storage mechanism is located between the right side plate and the middle partition plate, it is a two-stage gear reduction mechanism, it can be operated electrically or manually when storing energy, it has the advantages of anti-reversal and mechanism clutching device, smooth movement, low noise, high efficiency, etc.; the two closing springs are respectively arranged in the outside of the mechanism on both sides, the force is uniform and the stability is good.

Split trip detacher adopts horizontal arrangement, manual detacher button and detacher into one. The closing solenoid is moved to the center position of the front of the mechanism and installed vertically. All of the release buckle are straight pull type release, its structure is simple, flexible and reliable action.

Electrical control unit consists of a shop-assisted switch, magnetic blowing switch, terminal row, silicon bridge stack rectifier blocks and other components.

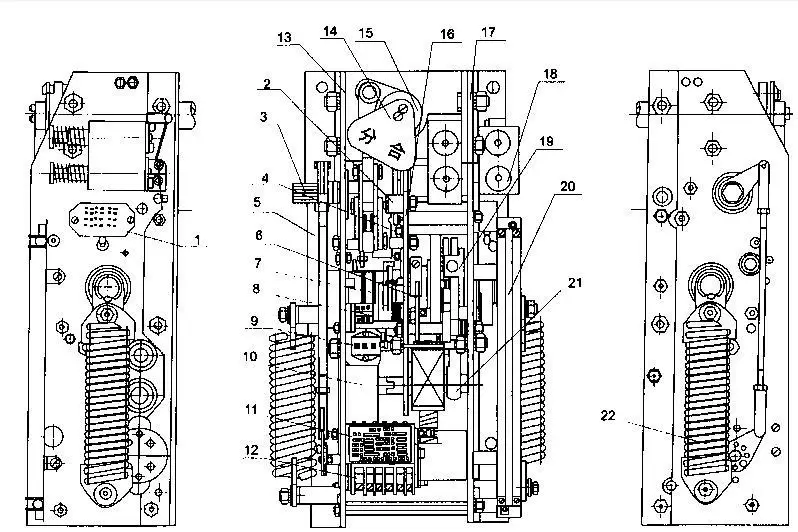

5.3 Principle of electric energy storage

See Figure 2 electric energy storage mechanism schematic, it adopts two-stage gear reduction structure, the motor from the gear shaft end of the input power, gear A and gear B constitute the first stage of gear transmission, gear C and gear D constitute the second stage of gear transmission, gear D rotates at the same time drive the drive claw, drive claw in the process of movement with the drive block drive after the drive energy storage shaft drive,

and then realize the energy storage for the closing spring spring energy storage, the spring storage in place, the rocker arm to promote the magnetic blow switch, cut off the motor power. When the spring energy storage is in place, the rocker arm pushes the magnetic blow switch to cut off the power supply of the motor. At the same time, the clutch cam will drive the claw lift up from the drive block, from the surface to ensure that the energy storage mechanical system under the action of inertia and not damage.

Translated with www.DeepL.com/Translator (free version)5.4 Manual storage operation Insert the energy storage handle (approx. 500 mm, accessory) into the energy storage

rocker hole and swing it up and down (approx. 35°), then the pawl on the rocker arm will drive the ratchet wheel and rotate the energy storage shaft to realize the energy storage of the closing spring.

5.5 Principle of closing and opening action

Drive mechanism unit Decoupling unit Fig. 2 Schematic diagram of the energy storage unit

Energy storage mechanism unit

|

Electrical control unit |

|||||

|

1,Flashing wheel A |

2,Hanging spring shaft by |

3,Closing spring |

|||

|

Figure 1 ↑ |

4,Gear B |

5,Gear C |

|||

|

CT19N type structure schematic diagram Combined overall fabric |

6,Clutch cam |

7,Stop pawl |

8,Drive block |

9,Rocker arm |

|

|

structure |

10, Magnetic blow switch |

11,Ratchet wheel |

12,Driving pawl |

||

|

13,Gear D |

14,Storage shaft |

||||

|

1,Wiring terminal |

2,Right side board |

3,Close gate solenoid |

4,Split gate solenoid |

|

|

5,Shutdown button |

6,Shutdown limit pin |

7,Middle board |

8,Shutdown limit arm |

|

|

9,Output shaft |

10,Left side plate |

11,Human power closing joint |

12,Connecting rod |

|

|

13,Cam |

14, Energy storage indication |

15, Auxiliary switch linkage village |

16, Closing spring |

|

|

17,Motor |

18,Auxiliary switch |

19,Name plate |

20,Gear |

|

|

21,Closing button |

22,Human energy storage rocker arm |

23, Magnetic Blow Switch |

||

Fig. 3 Schematic structure of CT19N model

1,Magnetic blow switch 2,Shutdown limit pin 3,Manual closing joint 4,Closing interlock 5,Auxiliary switch connecting rod

6,Close button 7,Camera 8,Energy storage indication 9,Counter 10,Motor 11,Nameplate 12,Auxiliary switch 13,Left side plate

14,Split-close indication 15,Output shaft 16,Middle board 17,Right side board 18,Split gate solenoid 19,Human energy storage rocker

20, Terminal 21, Closing solenoid 22, Closing spring

Figure 4 CT19W type performance structure diagram

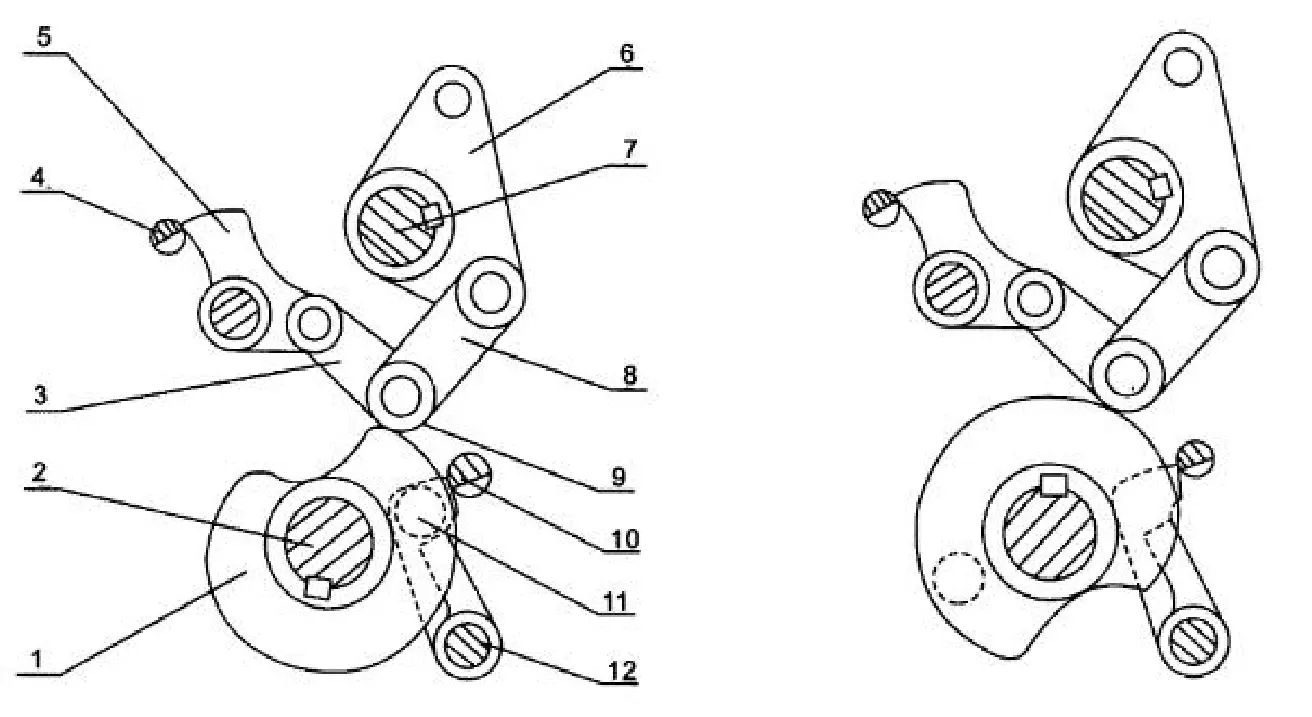

a,Closing with energy storage state b,Close without energy storage state

c,Shutdown with energy storage state d,Split gate without energy storage state

|

1,Cam |

2,Storage shaft |

3,Connecting plate |

4,Split half shaft |

5,Buckle plate |

|

|

6,Output crutch arm |

7,Output shaft |

8,Connecting plate |

9,Roller |

||

|

10,Closing half-axis |

11, cam roller |

12, Energy storage maintaining latch plate |

|||

|

Figure 5 Cam-linkage mechanism action principle |

|||||

|

schematic diagram |

|||||

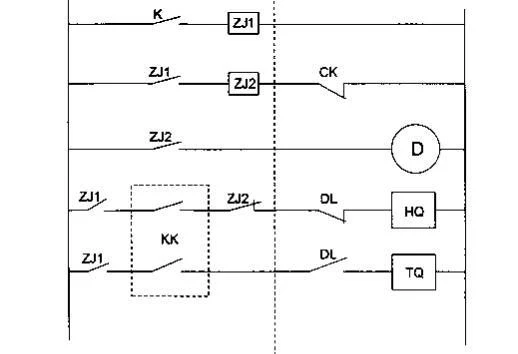

Control Circuit

Internal circuit of the organization

K-Switch

KK -Control switch

CK-Magnetic blow switch

DL -Auxiliary

switch

D-Motor

HQ-Closing coil

TQ -Shutdown coil

ZJ -Intermediate relay

Fig. 6 Schematic diagram of control circuit (mechanism is in disconnected state without energy storage)

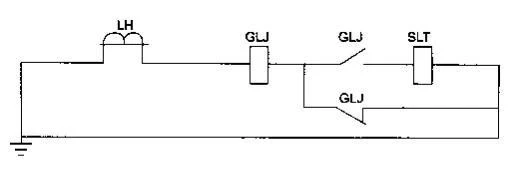

LH - Current Transformer CIJ - Over-current Relay

SLT - Mechanism over-current release coil or electromagnet coil

Note:

When the secondary output capacity of the current transformer is sufficient, the indirect over-current release scheme is selected; when the secondary output capacity of the current transformer is not enough to provide the over-current release solenoid demand, the intermediate transformer scheme is selected.

Figure 7 over-current protection system electrical schematic diagram

The closing and opening operation of the mechanism is realized by the cam-link mechanism, and Fig. 5 is the schematic diagram of the action principle of the cam-link mechanism.

5.5.1 Closing operation:When the mechanism closing spring energy storage is completed, the cam - linkage mechanism is in the state shown in (Fig. 5a), the closing spring due to the action of the sincerity and keep in the state of energy storage. The energy storage to keep the beryllium buckle plate under the action of the cam roller force has a tendency to unbuttoning direction (clockwise) movement, at this time, if the closing half-uranium according to the clockwise direction of rotation to the position of the unbuttoning (about 20 degrees or so), the energy storage to keep the beryllium buckle plate will be to the clockwise direction of the rapid movement of the energy storage to maintain the state that is lifted, the closing spring rapid release of energy, it drove the cam along the clockwise direction of rotation, at the same time, the connecting rod mechanism In the cam driven movement to the closing position - Figure 5b position, thus completing the mechanism of the closing action, at this time if you continue to make the closing spring energy storage in place, the cam a linkage mechanism will reach the state shown in Figure 5a.

5.5.2 Opening operation: the closing state of the mechanism is maintained by the linkage mechanism of the buckle plate and half-axis, buckle plate in the circuit breaker under the action of the load force, there is a tendency to unbuttoning direction (counterclockwise) movement, at this time, if the half-axis will be divided along the counterclockwise direction of rotation to the position of the unbuttoning (about 20 degrees or so), the buckle plate will be rapidly along the counterclockwise direction, the linkage mechanism of the equilibrium is lifted in the circuit breaker under the action of the load force to move to the breaking position (about 20 degrees), the linkage mechanism will be quickly along the counterclockwise direction of the movement of the balance, in the breaker load Under the action of the force, the linkage mechanism will move to the breaking position - Fig. 5c or Fig. 5d, thus completing the mechanism's breaking action, and the state shown in Fig. 5d is the mechanism's free release state.

6 Electrical control principle and internal wiring

6.1 Electrical control principle: Figure 6 for the control circuit schematic diagram, when the mechanism is in the tripping without energy storage state, the magnetic blowing switch CK normally closed contacts on, at this time close the switch K, the intermediate relay ZJ1 action, ZJ1 normally open contacts closed, the intermediate relay ZJ2 action, ZJ2 normally closed points open, ZJ2 normally open points closed, the motor and the power supply is connected to the spring to start the closing of the energy storage. If the closing spring does not store energy in place, i.e. the normally closed contact of the magnetic blow switch CK is not opened, at this time, even if the control switch KK is thrown to the closed position, the closing coil HQ will not be energized, in order to avoid malfunctioning.

After the energy storage is completed, the normally closed contact of the magnetic blow switch CK is opened, the intermediate relay ZJ2 is powered off, and its normally open and normally closed contacts are restored to the initial state, and the motor is powered off and stopped. At this time, if the control switch KK is thrown to the closed position, the closing trip coil HQ will be energized to make the solenoid act, the mechanism is to close the gate operation.

After the mechanism is closed, the normally closed contact of the auxiliary switch DL opens, and the power supply of the closing detent coil HQ is cut off; the normally open contact closes. At this time, if the control switch KK cast to the position of the points, the tripping release coil TQ will be energized, so that the electromagnet action, that is, the mechanism for the opening operation. After the mechanism is opened, the normally open contact of the changeover switch is opened, and the power supply of the tripping release coil TQ is cut off.

The magnetic blow switch CK has another pair of normally open contacts for energy storage signal indication.

The auxiliary switch DL has an additional set of normally open and normally closed contacts for closing and opening signal indication.

6.2 The electrical principle of the over-current protection system is shown in Figure 7.

The over-current tripping solenoid coil of the mechanism is powered by the current transformer, and its circuit is closed by the action of the contacts of the over-current relay. The action value of the over-current protection is set by the over-current relay.

Note:

The polarity in the dotted box should be the same, DL-2 and DL-4 are not wired when the mechanism requires three over-current.

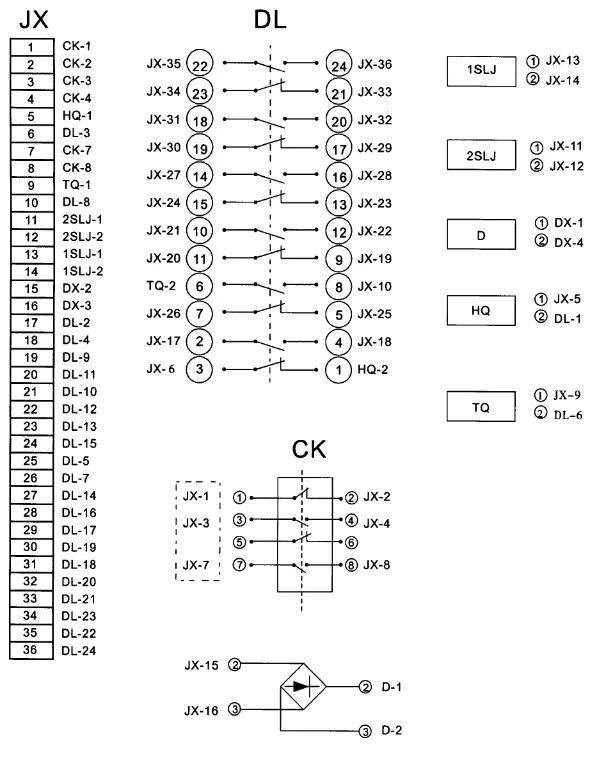

6.3 The internal wiring diagram when the spring-operated mechanism is in the tripping state is shown in Figure 8.

7 Mounting and adjustment

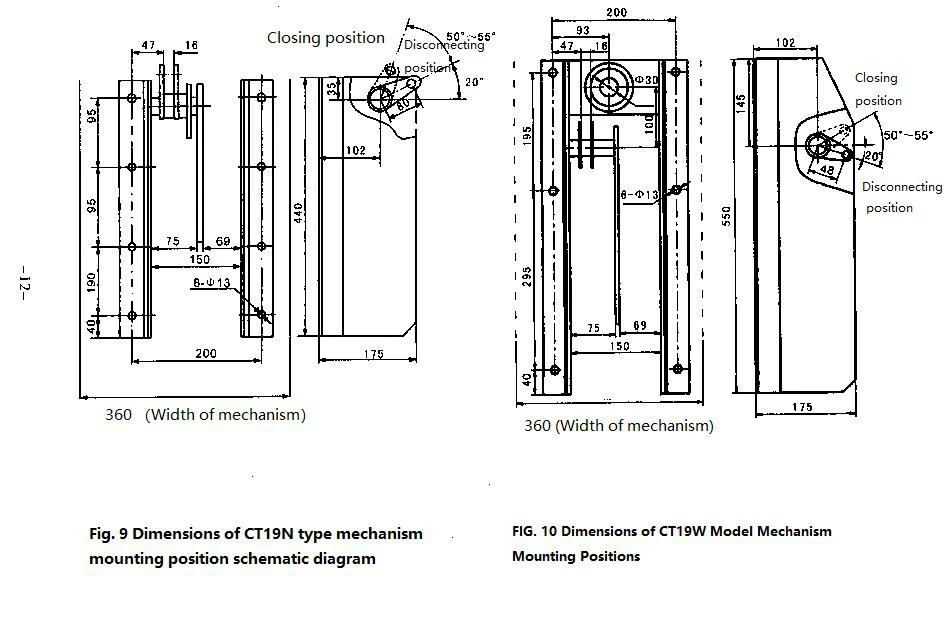

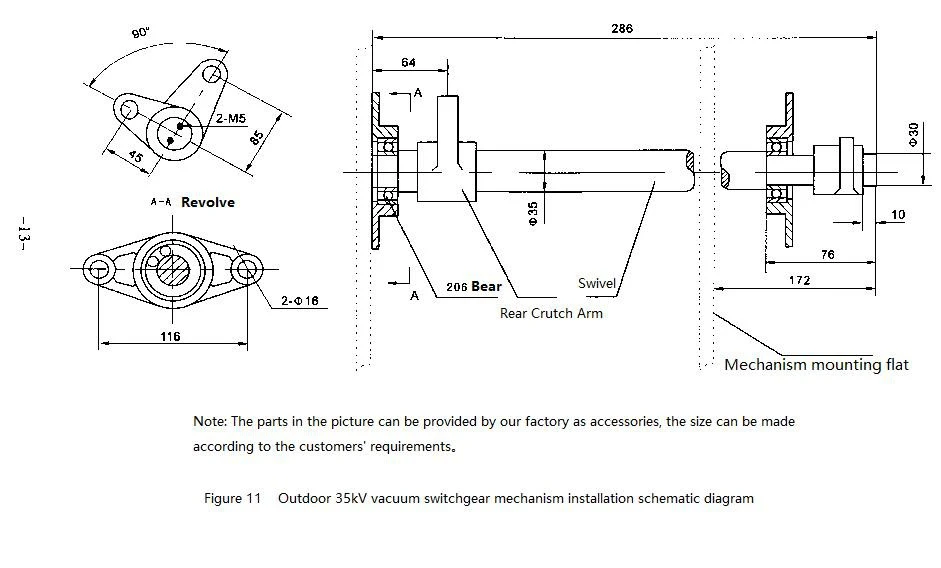

7.1 Figure 9 shows the installation dimensions of the CTI9N type mechanism, and Figure 10 shows the installation dimensions of the CT19W type mechanism. Figure 11 shows the installation schematic of the horizontal drive major shaft of the outdoor switch-gear. Installation of the body of the mechanism with M12 bolts fixed in the switch-gear panel or the corresponding support, and then install the horizontal drive shaft, and then used to gently rotate the horizontal drive shaft, the shaft rotation must be very flexible, there shall be no sense of blockage. Finally, install the output shaft of the mechanism and the horizontal drive shaft connected to the small clamping fork, installed to connect the horizontal drive shaft and vacuum circuit breaker connecting rod, do a few minutes to close the action, to see whether the action is flexible and reliable, closing instructions are correct in place. The switchgear panel or corresponding support of the mounting mechanism should be flat and have sufficient strength and rigidity, and there should be no obvious tilting after the installation of the mechanism, and there should be no deformation that affects the flexible movement of the mechanism.

7.2 The mechanism, as a relatively independent element, can be used in many types of vacuum circuit breakers, but the cooperation between the mechanism and the circuit breaker affects whether the mechanism can meet the requirements of the mechanical characteristics of the circuit breaker. Therefore, the mating relationship between the mechanism and the corresponding circuit breaker is generally determined by the supporting family.

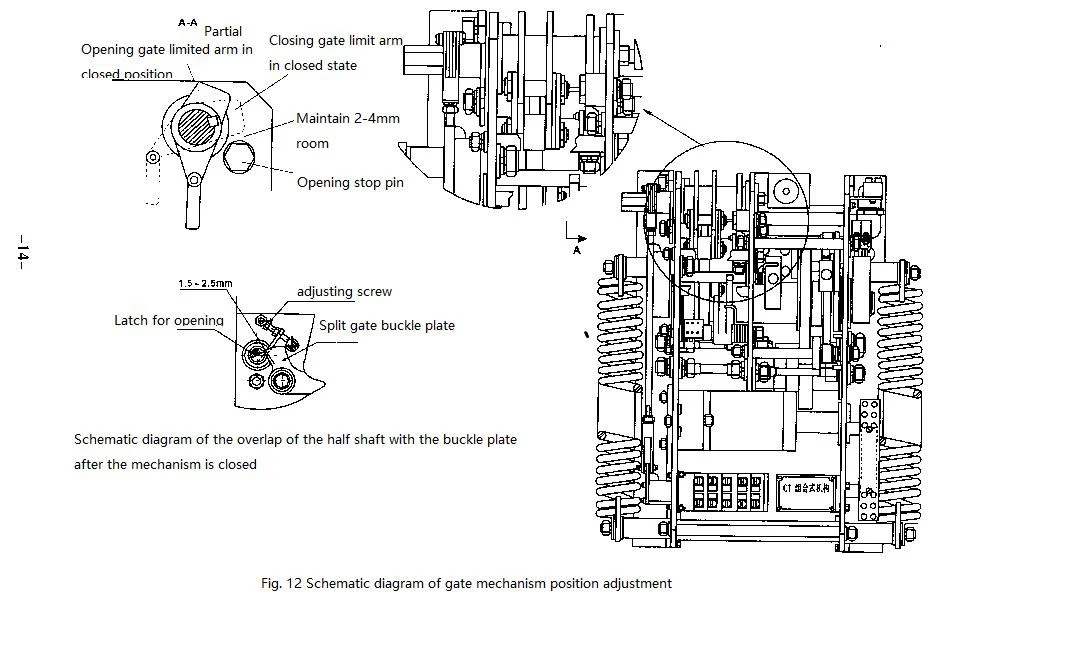

7.3 The coupling between the mechanism and the circuit breaker should be carried out when both the circuit breaker and the mechanism are in the open position, and the correct position of the mechanism when it is in the open state is shown in Fig. 12. After the coupling between the mechanism and the circuit breaker, when the mechanism is in the tripping position, there should be 2-4mm clearance between the tripping limit inflection arm of the mechanism and the tripping limit axle pin, and at this time, the output turning angle of the mechanism is 50-55°. Special attention should be paid to the mechanism of the tripping limit inflection arm and the tripping limit axis pin can not be used as the circuit breaker's tripping limit, otherwise it may cause damage to these two parts, when the mechanism of the tripping limit inflection arm and the tripping limit axle pin leaning far away, it may also cause the mechanism refuses to close.

After coupling the mechanism with the circuit breaker, when the mechanism is in the tripping and has stored energy state (refer to Fig. 5), the mechanism's buckling plate should be moved to the position of detachment from the tripping half-axis, so that the tripping half-axis is completely free to reset. Otherwise, it means that the mechanism's breaking position is not correct, and the mechanism's breaking position should be adjusted by adjusting the coupling between the mechanism and the circuit breaker, and the mechanism's breaking position should be adjusted by adjusting the connection between the mechanism and the circuit breaker.

7.4 After connecting the mechanism with the circuit breaker, the mechanism should firstly

carry out the slow division and slow closing action, in order to check and exclude the jamming phenomenon of the whole mechanical transmission system. The mechanism of the slow closing and slow action can be realized by the board hand through the rotation of the mechanism output shaft of the human power to close the joints. Note that in the slow human slow closing operation, do not have to be forced to close the gate in place, so as to avoid damage to the mechanism.

8 Use and maintenance

8.1 Before using the mechanism, you should check whether the rated voltage (current) of the motor, coil and other electrical components on the mechanism is in line with the requirements, and check whether the mechanism has been damaged by parts (e.g., due to improper transportation), loose fasteners, and disconnected wires.

8.2 Before operating the mechanism for the first time, each transmission part of the mechanism should be properly lubricated.

8.3 The mechanism should be lubricated and inspected periodically during operation.

8.4 When the mechanism is under normal maintenance, the energy of the closing spring should be released first: the method of releasing the closing spring can be to drive the circuit breaker to carry out a "closing-splitting" operation (at this time, the motor should be disconnected so as not to store the energy again), or in the state of the circuit breaker splitting the circuit breaker with a manual splitting button to open the splitting half-axis and the buckling of the buckle plate, and then The closing signal (electric or manual button) is given to the closing spring to release energy without load.

8.5 The mechanism has an interlocking device for closing operation, which can only be carried out when the mechanism is in the opening position. Therefore, when the mechanism is not connected to the circuit breaker and the closing spring has stored energy, the output shaft of the mechanism should be adjusted to the opening position first, and then carry out the above no-load energy release operation.

8.6 The operator should understand the structure, performance, installation, adjustment, maintenance and repair knowledge of the mechanism so that the operator can use it.

9 Transportation and Storage

9.1 When the mechanism is transported, the whole unit must be encapsulated in a wooden box, and through the mounting holes on the mechanism (4 Ф13 holes) with M12 bolts to fix the mechanism on the wooden base plate.

9.2 Packing, unpacking and storage should be carried out in a dry room, pay attention not to damage the parts of the organization.

10 Attachments with the equipment

|

Specification |

No. |

Name |

Unit |

QTY |

Notes |

|

CT19N |

1 |

Link Rod |

set |

1 |

|

|

2 |

Charging Handle |

pcs |

1 |

||

|

CT19W |

1 |

Opening and closing indicator |

pcs |

1 |

|

|

2 |

Lever,clamp and screw |

set |

1 |

||

|

3 |

Output driving shaft |

pcs |

1 |

||

|

4 |

Driving lever |

pcs |

1 |

L=280mm |

|

|

5 |

FL206 bear |

pcs |

1 |

Hole pitch is 8.5mm |

|

|

6 |

5x60 Elastic cylindrical pin |

Pcs |

4 |

||

|

7 |

8x60 Elastic cylindrical pin |

pcs |

4 |

||

|

8 |

Charging Handle |

1 |

|||

Documents 11.1 Certificate

11.2 Installation and use instructions.

11.3 Packing list.

Notes for ordering:

When ordering, please specify the details as below:

12.1 The model, specification and quantity of the mechanism.

12.2 The rated operating voltage of the mechanism (storage voltage, closing voltage, opening voltage);

12.3 The rated short-circuit breaking current value of the matched circuit breaker (switch-gear); 12.4 Over-current release solenoid (optional);

12.5 Rated short-circuit breaking current value of the mechanism;

12.6 Rated short-circuit breaking current value of the matched circuit breaker (switch-gear)

12.4 Number and rated current of over-current release solenoid (it's optional).

12.5 Other special requirements for the mechanism.

OEM/ODM Services:

At Shaanxi Yuguang Electric Co., Ltd., we understand the importance of customization. That's why we offer comprehensive OEM and ODM services to meet your specific requirements. Whether you need private labeling or custom product development, our experienced team is here to assist you every step of the way.

Certificates:

We take pride in our commitment to quality and safety. Our products are certified to meet the highest industry standards, including:

3C Certification

ISO 9001 Certification

21 Utility Model Patents and Design Patents

Why Choose Us:

State-of-the-art Manufacturing Equipment

Extensive Testing Facilities

Comprehensive Quality Assurance Processes

ISO 9001 Certified Quality Management System

One-year Warranty on All Products

Large Production Capacity

FAQ:

Q: What is the warranty period for your products? A: We offer a one-year warranty on all our products.

Q: Can you customize products according to our specifications? A: Yes, we provide OEM and ODM services to meet your specific requirements.

Q: Are your products compliant with international standards? A: Yes, our products meet all relevant international standards.

Q: What is the lead time for orders? A: The lead time depends on the quantity and customization requirements. Please contact us for more information.

Q: Do you provide technical support? A: Yes, we offer comprehensive technical support to our customers.

Packaging:

Wooden Box Packaging

Carton Packaging

Foam-filled Packaging

Waterproof and Moisture-proof Packaging

Customized Packaging

International Standard Packaging

Logistics:

Sea Freight

Air Freight

Land Transportation

Multimodal Transport

Express Delivery Services

Contact Us:

Ready to take your electrical projects to the next level? Contact us today at ygvcb@hotmail.com to discuss your requirements and explore partnership opportunities with Shaanxi Yuguang Electric Co., Ltd. Let's create a brighter future together.