LBS-12/630 Outdoor Load Switch

- Free Samples

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1,Overview

Column installed insulation load switch,LBS-12/630 outdoor load switch,is suitable for the rated voltage 12/24/40.5kV,rated current 400A,630A,50/60Hz power grid open circuit,load current in closed Power system,overload curren. This load switch can separate those broken distribution line automatically.

With the latest technology, it has the newest electronic controller.The switch can be used by manual operation, electric operation and operation from a long distance. Electronic controller is installed in a stainless steel cabinet which is suitable for using under all kinds of climatic conditions. In addition, there are some wired and wireless modem installed in the cabinet through which it can realize the remote monitoring and control. Simple installation on column is convenient, fast, and also can reduce the construction cost.

2,The standard conditions of use

This outdoor load switch ADAPTS to operating conditions:

2.1 Ambient temperature

2.1.1 Ambient air temperature: upper limit +50 ° C, lower limit of -40 ℃.

2.1.2 Relative Humidity: 100%

2.2 Elevation does not exceed 1000m;2000m;3000m;5000m

2.3 The pressure does not exceed 700pa (equivalent to wind speed of 34m / s).

2.4 Earthquake intensity: 8 degrees.

2.5 Installation site: No fire, no explosion hazards, no chemical corrosion and recurrent severe vibration.

2.6 Pollution class: class III, class IV.

3 FeaturesFeatures

3.1 SF6 gas-insulated

3.1.1 SF6 gas is a kind of nontoxic, nonflammable and electrical insulating gas. It has the excellent characteristic of arc extinction.

3.2 Drivepipe with large diversity

3.2.1 In addition to the standard ceramic drivepipe, we can also provide a variety of solutions, including rubber insulators used in the epoxy resin filling equipment

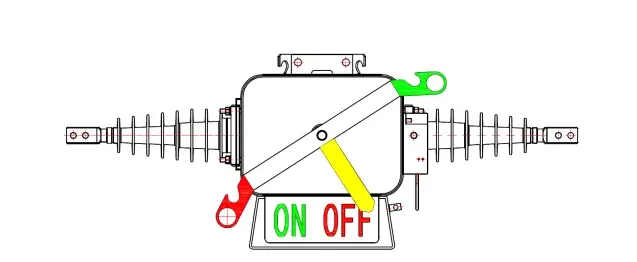

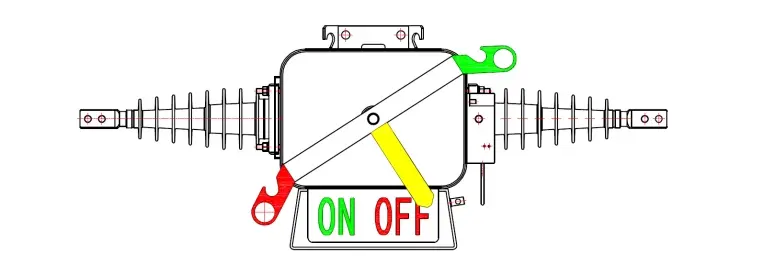

3.3 Visible open / closed status

3.3.1 It is easy to see the main contact position indicator which is color-coded just standing on the ground (Green - off; red - closed). The indicator is directly connected with the main contacts of the drive shaft assembly to ensure accurate display of contact states.

3.4 Quick operation

3.4.1 operating mechanism with spring energy to ensure a quick closing and opening operation (less than 100 milliseconds).

3.5 Can realize remote control

3.5.1 It is equipped with electronic controller, fit for in situ operation as well as FTU interface console operation.

3.6 Rugged switch

3.6.1 The switch is made of proven durable, corrosion-resistant materials (special used in warships 304L stainless steel plate)which ensures that there is a very long service life (30 years), and can be implement a series of operations.It has the ideal characteristics as a column equipment.

3.7 Standard

3.7.1 Each switch before leaving the factory has been filled with SF6 gas, sealed, and test according to IEC60265-1 (1988), GB40.504-1990 standard.

4 Type and Rating

4.1 Product mode

LBS-12/630

4.3 LBS Type of the outdoor load switch

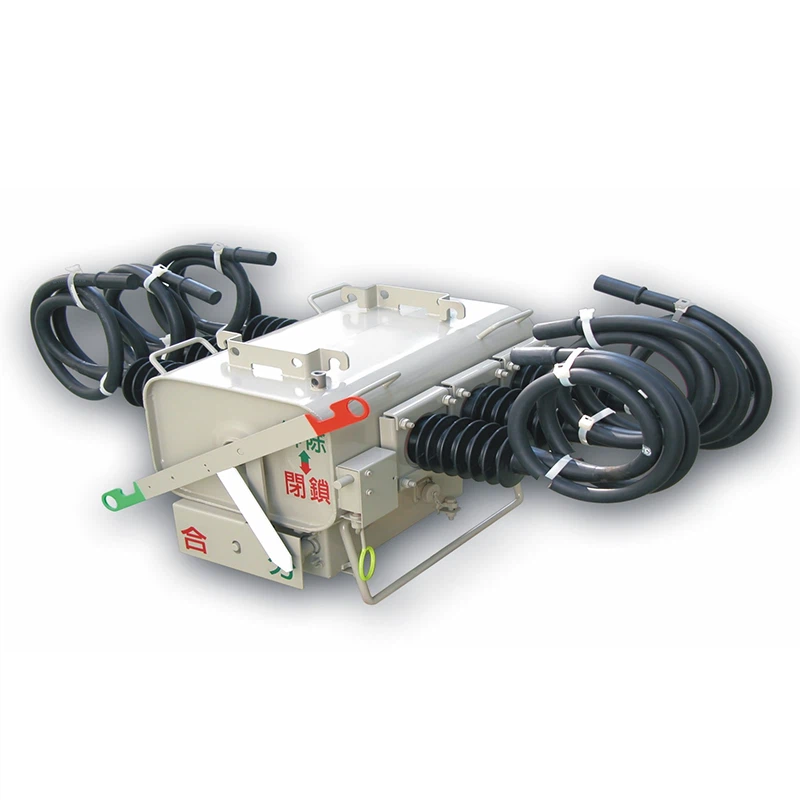

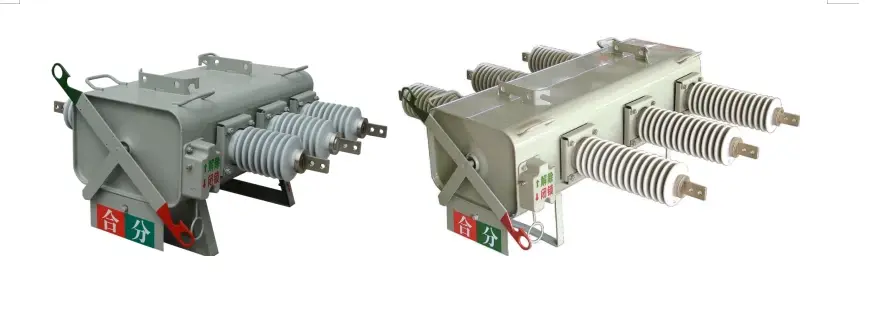

Figure 1) ceramic bushing - molded cable outlet Figure 2) rubber split bushing - molded cable outlet

Figure 3) rubber bushing - terminal outlet Figure 4)with a lightning arrester

Figure 5) ceramic bushing - terminal outlet

4.4 Parameters ratings

Table 1

|

No. |

Name |

Unit |

Data |

|||||

|

Product mode |

LBS-12 |

LBS-22 |

LBS-40.5 |

|||||

|

1 |

Rated voltage |

kV |

12 |

22 |

40.5 |

|||

|

6/10/11 |

15/17.5/22 |

33/36/40.5 |

||||||

|

2 |

Rated frequency |

Hz |

50/60 |

50/60 |

50/60 |

|||

|

3 |

Rated insulation level(The filling SF6 gas 0.07Mpa / 20 ° C) |

(Lightning impulse withstand voltage) |

relatively |

kV |

75 |

125 |

185 |

|

|

Fracture |

85 |

145 |

215 |

|||||

|

Power frequency withstand voltage 1min |

relatively |

kV |

42 |

64 |

95 |

|||

|

Fracture |

50 |

79 |

110 |

|||||

|

4 |

Insulation level of zero gauge pressure. |

Power frequency withstand voltage 1min |

kV |

30 |

||||

|

RP-pressure 1min |

30 |

|||||||

|

The highest phase voltage 5min |

9 |

|||||||

|

5 |

Rated current |

A |

630(400) |

630(400) |

630(400) |

|||

|

6 |

Rated breaking load current (0.07Mpa / 20 ° C) |

A |

630(400) |

630(400) |

630(400) |

|||

|

7 |

breaking current under zero gauge pressure |

A |

630(400) |

630(400) |

630(400) |

|||

|

8 |

peak withstand current |

kA |

50 |

50 |

50 |

|||

|

9 |

Rated short time making current |

kA |

50 |

50 |

50 |

|||

|

11 |

rated short time withstand current |

KA/s |

20/4 |

20/4 |

20/4 |

|||

|

12 |

rated cable charging breaking current |

A |

25 |

25 |

25 |

|||

|

13 |

rated line charging breaking current |

A |

16 |

16 |

16 |

|||

|

14 |

rated closed-loop breaking current |

A |

630(400) |

630(400) |

630(400) |

|||

|

15 |

exciting current |

A |

21 |

21 |

21 |

|||

|

16 |

rated current breaking times |

Times |

≥400 |

≥400 |

≥400 |

|||

|

17 |

rated working pressure |

MPa |

0.07 |

0.07 |

0.1 |

|||

|

18 |

Per-phase main circuit resistance |

μΩ |

≤150 |

≤180 |

≤200 |

|||

|

19 |

relative gas leakage rate |

year |

≤1% |

≤1% |

≤1% |

|||

|

20 |

SF6 gas moisture content |

Factory transfer of value |

ppm |

≤150 |

≤150 |

≤150 |

||

|

Switch running value |

ppm |

≤300 |

≤300 |

≤300 |

||||

|

21 |

operation of echanical stability |

times |

6000 |

6000 |

6000 |

|||

|

22 |

rated operating voltage and auxiliary circuits rated voltage |

V |

DC 220/ 110/48/24 |

DC 220/ 110/48/24 |

DC 220/ 110/48/24 |

|||

|

AC 220/110 |

AC 220/110 |

AC 220/110 |

||||||

|

23 |

Weight |

Type M |

kg |

115 |

125 |

135 |

||

|

Type A |

135 |

145 |

155 |

|||||

|

24 |

institutions boxes and controller protection class |

IP44 IP54 |

||||||

|

25 |

Type of Mounting |

The lifting type (suspended)/block (horizontal) |

||||||

5. Structure

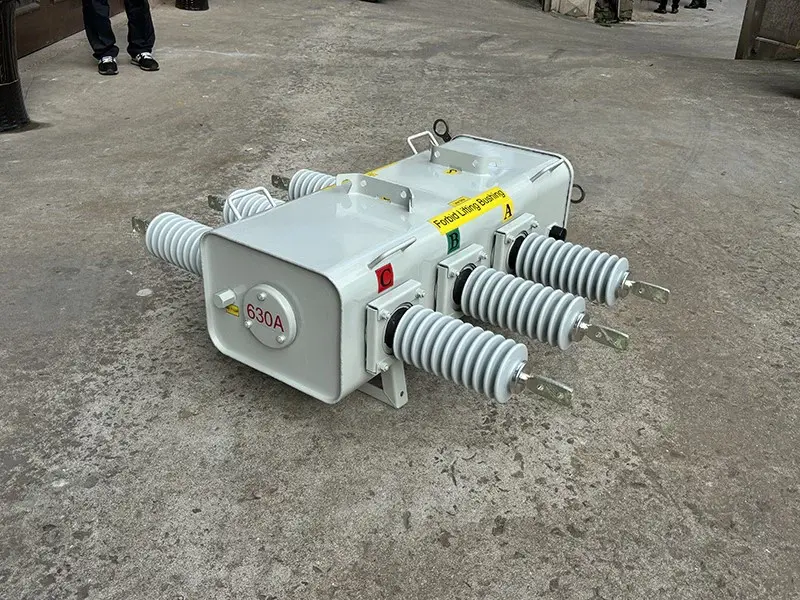

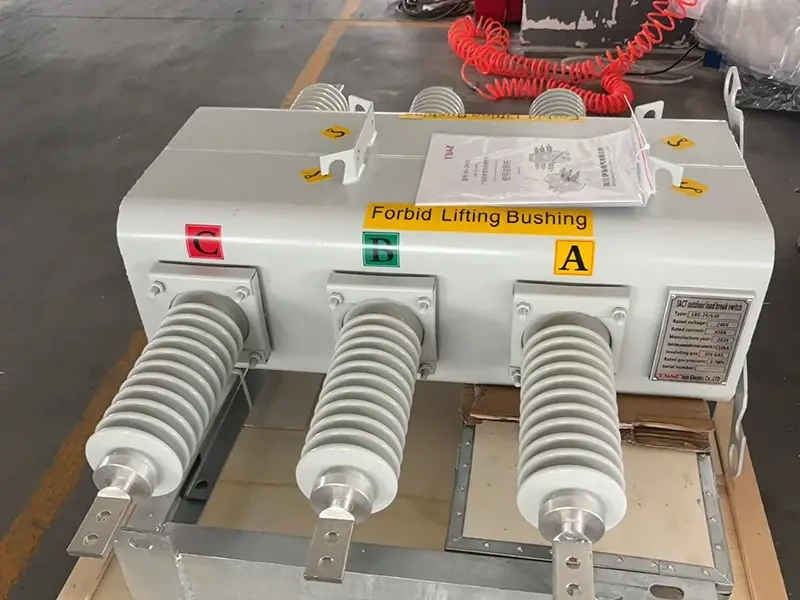

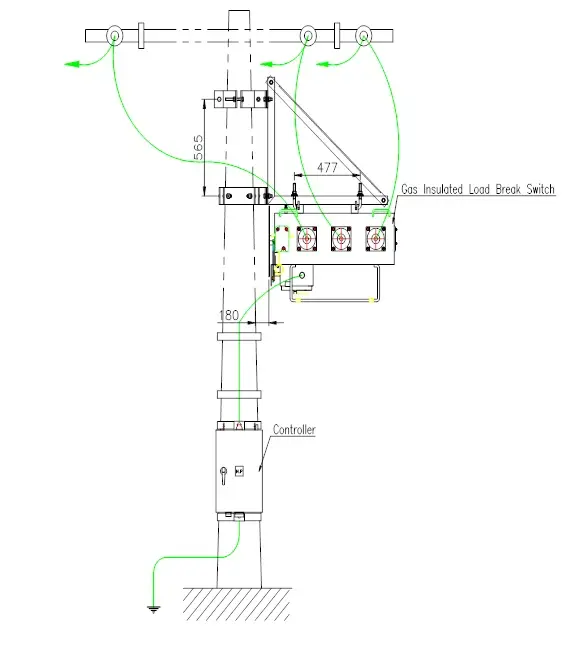

5.1 switch and controller appearance (Model:LBS-12/630)

Connection diagram

The appearance and size of the switch(see table 2)

|

Dimensions(mm) |

Installation dimentions(mm) |

Casing creepage distance(mm) |

|||

|

A |

B |

C |

Long x width |

||

|

12Kv |

225 |

435 |

500 |

500×125(280) |

556 |

|

24kv |

300 |

435 |

500 |

500×125(280) |

840 |

|

40.5Kv |

350 |

435 |

500 |

700×125(280) |

1250 |

(table 2)

5.3 The switch body

5.3.1 SF6 gas insulated switchgear is a three-phase linkage operation switch device designed for the distribution system cables and overhead power line segment applications. It can be manually operated on the scene or also can be controlled from control center.

5.3.2 The switch body using welding to seal the casing and the casing using rubber ring seal, and all the other parts are assembled in the welding of stainless steel tank shell.

5.3.3 The switch body designed to be able to withstand pressure without affecting the switch to normal operating performance.

5.3.4 The shell casing is made of a thickness exceeding 3 mm cold-rolled stainless steel (SUS 304L) or better materials to withstand the internal gas pressure.

5.4Insulating gas

Figure 8) temperature - pressure curve

Inflation pressure (0.7 kg/cm2G)

Rated working pressure (0.7kg/cm2G)

High-pressure relief explosion-proof device operating pressure (4-6 kg/cm2G)

Atresia of low pressure alarm device closure pressure (0.3-0.4kg/cm2G)

5.4.1 SF6 gas, which is used in the LBS is a high-purity products, specifically designed and manufactured to ensure that the gas in the shell of the load during the switching operation of the water content below 300 ppm.

5.4.2 About LBS switch gas temperature range and gas leakage, inflation pressure, the rated working pressure, minimum working pressure, the maximum relief pressure, the lowest gas closure pressure .etc, please see Figure 8.

5.5 The switch fabric

5.5.1 Manual operating handle.

LBSuses high voltage insulation lever to safely operate its structure to a one-time operation is completed on or off.

Figure 9) Manual operation handle

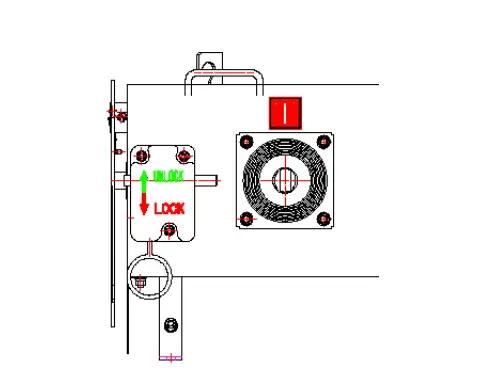

5.5.2 Manual locking device

Power outage operation, set to prevent the switch misuse. Please pull down the manual mechanical locking device to pull the ring to switch bodies locked in the "on" or "off" position. We can no longer operate

when the switch is in the closing or sub-gate state. When the operation is completed, push up the manual mechanical locking device to ring-pull to unlock the switch mechanism which ensures the operating's reliability, security.

Figure 10) Manual locking device

5.5.3 contact position indicator

it is easy to see color-coded switch to division and position indicator standing on the ground (Green - off; red - closed).

Figure 11) contact position indicator

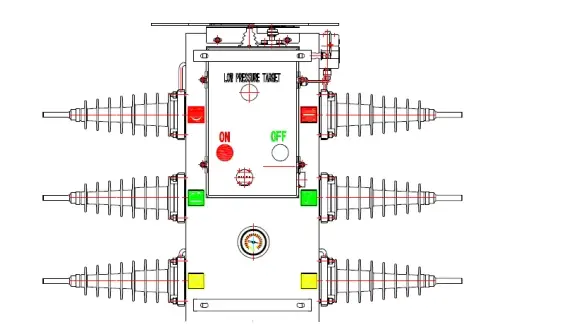

5.5.4 low pressure warning device

When the pressure dropped to 0.3 ~ 0.4kgf/cm2. Equipped with automatic locking device action, switch lockout, It cannot be manual operated nether can not be electrically operated. There are also instructions to remind the red alarm signs.

Figure 12) low pressure lockout indicator device

5.5.5 High pressure relief alarm device

In order to prevent a sharp rise of the switch due to the internal exception and cause the gas pressure result in container rupture, set up a special high-pressure explosion-proof pressure relief device; vent lamination action 0.4MPa ~ 0.6MPa (4-6 kg/cm2G) pressure, the release of internal pressure. The high-pressure explosion-proof pressure relief device installed at practicing hand operating handle in the opposite direction, to avoid vent lamination rupture endanger the operator and public safety.

Figure 13) high pressure relief explosion-proof device

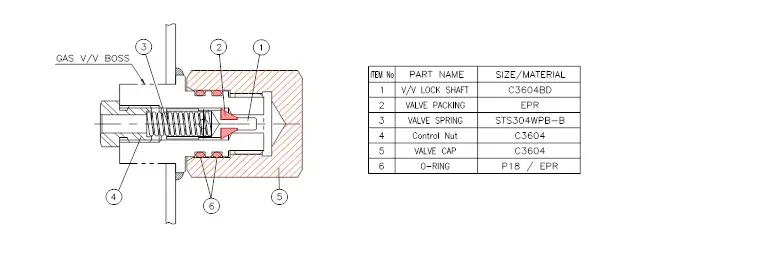

5.5.6 inflation valve

Equipped with this valve so that when required to switch shell filling SF6 gas.

Figure 14) Pneumatic valve

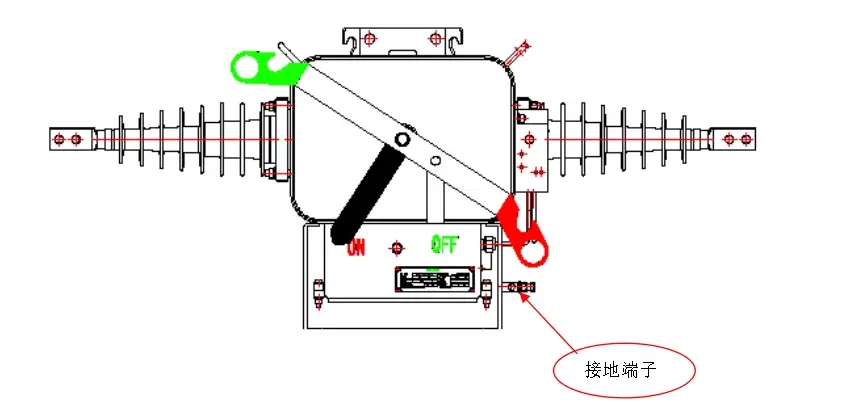

5.5.7 The grounding terminal

Switching the front of the shell above / the underside of a φ13 stainless steel grounding Luo column, for the installation of the grounding lines. Its structure without the use of additional auxiliary clip will be able to easily use 22 to 40.5 mm2 copper wire and ground connection.

Figure 15) ground terminal

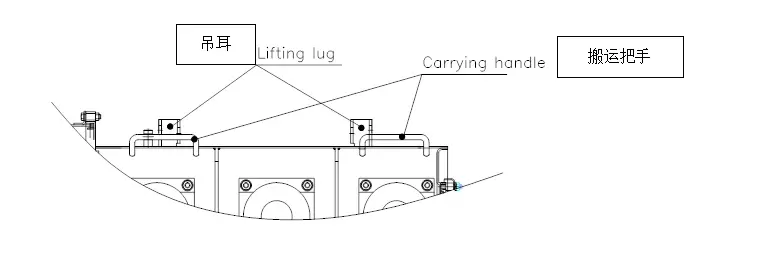

5.5.8 lug

The main box on top of the four transport lug, and four carrying handles for easy handling and lifting.

Figure 16) Lifting lug

Carrying handle

Lifting lug

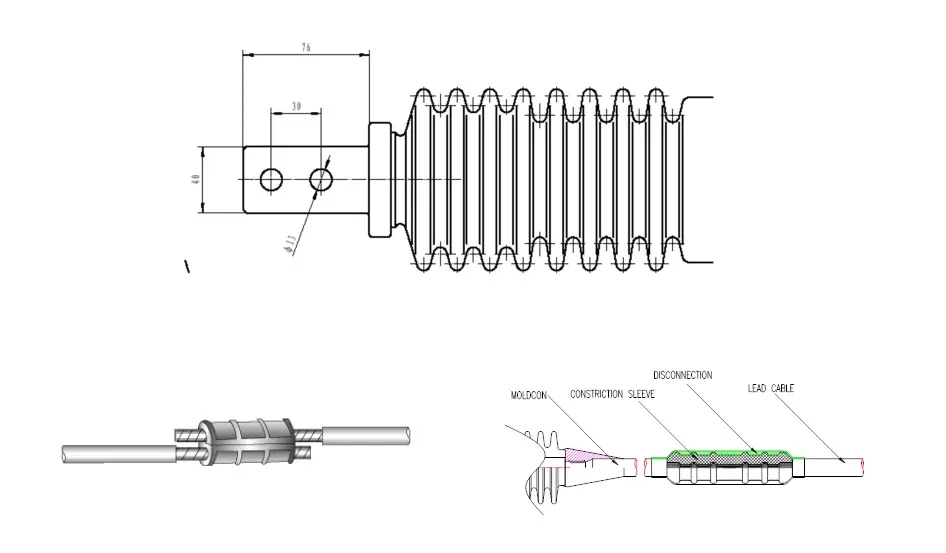

5.6 Polymer rubber casing

Figure 17) rubber casing Figure 18) terminal of rubber and rubber molded cable

5.6.1 The casing material is an epoxy resin and EPDM rubber or ceramic.

5.6.2 The switch inlet and outlet casing ceramic casing and casing of organic insulator, the casing creepage distance: 576mm, leakage distance: 40.5mm/1kV.

5.6.3 porcelain casing firing, the alumina has a high dielectric strength and mechanical strength. Porcelain bushing shell to connect the parts coated with semiconductor paint, which can effectively prevent the corona discharge in the switch running.

5.6.4 Organic insulator sleeve is made of imported outdoor epoxy resin and silicone rubber, the complete elimination of rupture due to external forces and lightning caused the porcelain and cracking due to the porcelain factors greatly improve the reliability of the switch is running.

5.6.5 Organic insulator casing split installation. Switch epoxy resin inlet and outlet casing and switches as one. Casing according to the ANS / IEEE 40.56 design its standard connecting surface to the traditional cable elbow connector also can be used to rubber casing with connection.

5.6.6 bushing sheds and terminals (connection cable) as a whole. Switch mounting bushing sheds and terminals (connection cable) to tighten the bushing. Transport small size, can be convenient terminal block or wiring cable replacement and installation according to project needs, easy to install. Casing flange made of stainless steel, together with the shell grounded.

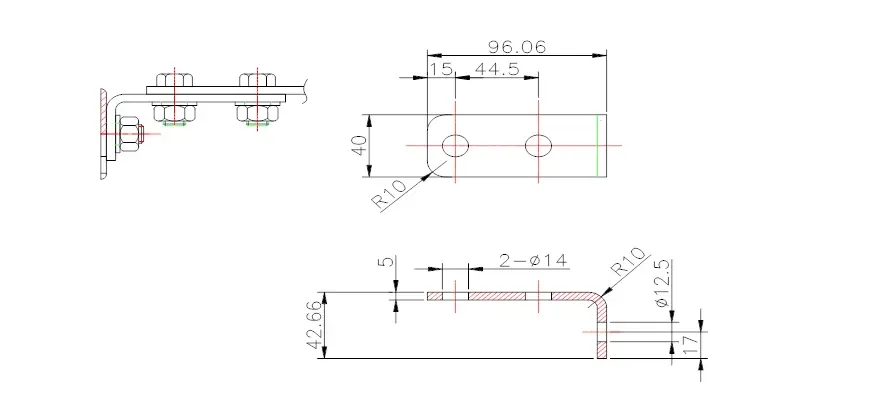

5.7 external connection terminal

5.7.1 molded cable lead, high-voltage insulated cables have a great deal of flexibility and good weather resistance, greater than 125 mm 2 (159/1.0) nominal cross section is used to 400A, 630A when the nominal cross section greater than 200 mm 2 (19/14/1.0), length of 1.5m to 2 m, optional.

5.7.2 The terminal type, terminal blocks for copper tinned with bus equipment clamp connection faying surface of the outlet terminals for 76mm x 40mm cross-section to allow the current of 630 A,.

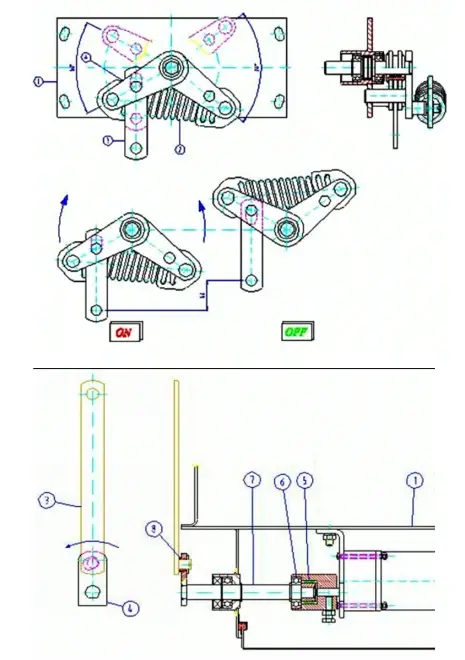

5.8 operating mechanism

5.8.1 The actuator seal in the switch gas cabinets, electric sector there are two kinds of (optional).

5.8.1.1 with a specially designed triangular spring operating mechanism, the use of dead flip the drive shaft contacts rapid division and the division speed depends on the spring energy largely independent role, and the external force. Of opening and closing speed and stability, institutions easy and reliab

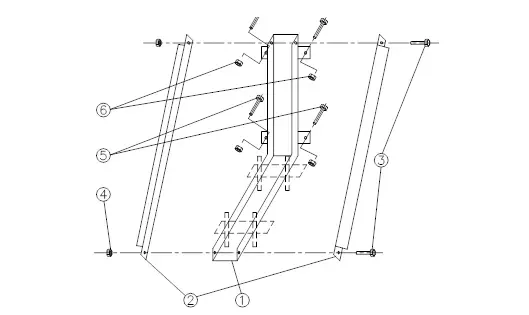

|

ITEM |

NAME |

|

1 |

Backplane |

|

2 |

Triangle crank |

|

3 |

Spring |

|

4 |

Link |

|

5 |

Closing instructions |

|

6 |

Tripping indication |

Figure)Operating mechanism

BEFORE THE MOVEMENT

DURING THE MOVEMENT

AFTER THE MOVEMENT

Main spring Link Cam

5.8.1.2Rapid spring actuator and to seal in the switch body, does not occur condensation, corrosion, can guarantee that the closing of the switch, opening speed is not because of the size of the power operation of technical proficiency and closing the power supply instabilityaffected, to ensure that the switch in the short-circuit state, with reliable breaking;

The operating mechanism uses a novel miniaturized spring operating mechanism, sub-gate open / close position to maintain the function of opening and closing low energy consumption

The operating mechanism is placed in the sealed box of institutions, to solve the corrosion problem of the institution, to improve the reliability of the agency. Switch points, closing operation can be manual or electric operation and remote operation of the instruction from afar.

Can be manually or electrically operated storage. After the switch is closed, the stored energy motor energy storage on the storage spring. After the end of the energy storage spring energy, the switch is in the ready state of the sub-gate; storage latch, so that agencies can not be re-charged.

Switch is closed, while opening spring energy storage. Institutions in the closing state and energy storage operations, the closing spring was again energy storage and atresia, avoid agencies mistakenly closing. Reclose storage state agencies in the coincidence state can achieve the "sub-0.3s-Hop sub" a reclosing operation.

Spring actuator, can guarantee the switch closing and opening speed is not because of the size of the power operation of skilled and closing of power instability affected to ensure that the circuit breaker short circuit condition, reliable breakingfunction;

The operating mechanism uses a novel miniaturized spring operating mechanism, sub-gate open / close position to maintain the function of opening and closing low energy consumption;

The operating mechanism is placed in the sealed box of institutions, to solve the corrosion problem of the institution, to improve the reliability of the agency. Switch points, closing operation can be manual or electric operation and remote operation of the instruction from afar.

Can be manually or electrically operated storage. After the switch is closed, the stored energy motor energy storage on the storage spring. After the end of the energy storage spring energy, the switch is in the ready state of the sub-gate; storage latch, so that agencies can not be re-charged.

Switch is closed, while opening spring energy storage. Institutions in the closing state and energy storage operations, the closing spring was again energy storage and atresia, avoid agencies mistakenly closing. Reclose storage state agencies in the coincidence state can achieve the "sub-0.3s-Hop sub" a reclosing operation.

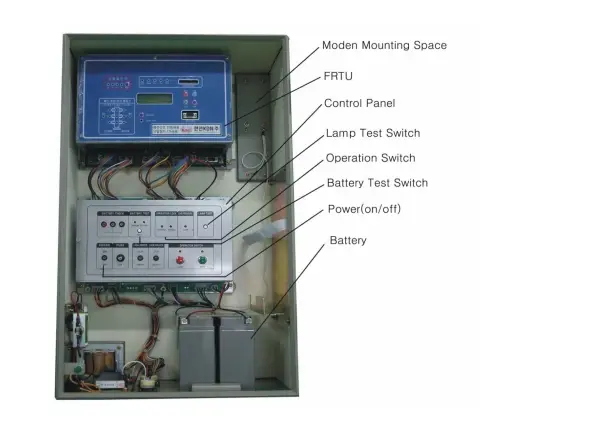

6.electronic automatic controller

Figure 20) Controller appearance

Modem mounting space

FRTU

Control Panel

Lamp Test Switch

Operation Switch

Battery Test Switch

Power (on/off)

Battery

6.1 Control box with a thickness exceeding 1.5 mm stainless steel plate, and the installation folder to install on a concrete pole.

6.2 The controller can operate in place of Pole,-LSB, but also can realize the remote control.SF6 gas pressure of

6.3 controllers monitor the Pole, - LSB.

If gas pressure drops below a preset threshold (0.3-0.4kg/cm2G), then the red ground board SF6 low pressure indicator will light, and electric and manual operation are locked.

6.4 Control box installed the following operations with display devices:

6.4.1 operating switch: closed; disconnect

6.4.2 Operation selection switch: local / remote

6.4.3 operating locking switch: lock / unlock

6.4.4 Charging the battery test terminals and test switch

6.4.5 lamp test switch

6.4.6 Control power switch (on / off) and fuse

6.4.7 Indicator

- Show Contact Status: Closed (red), disconnect (green)

- Show the gas pressure low lock

- Displays the switch operation lock (control box / box)

- Charge state of the components and rechargeable batteries

6.5 rechargeable battery and charging unit are as follows:

6.5.1 The control power supply with a rechargeable battery

- This is DC24V rechargeable power. A single charge can operate the switch for more than 500 times. Built-in rechargeable battery, able to maintain operation when AC power failure, more than 24 hours.

6.5.2 charge the battery and charging device

Necessary - according to the ambient temperature automatic control battery charge current. It includes protection circuitry to prevent overcharging or excessive discharge.

6.5.3 Charging the battery test terminals

- With test terminal can display charging status, and no-load to check the status of the battery voltage and charging device.

Inlet and outlet connection diagram

Figure 21) lug terminals to indicate

Figure 22) insulation through the connector Figure 23) crimping sleeve

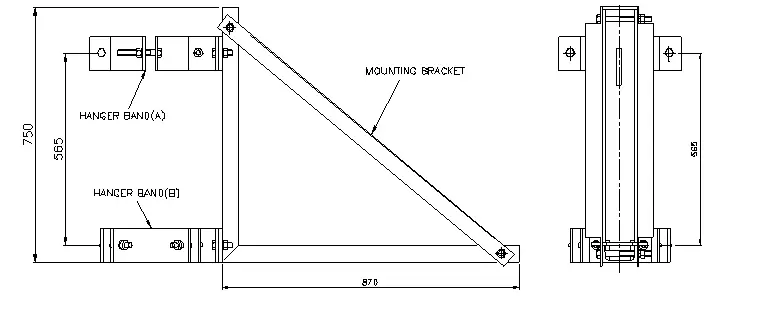

8. poles installed on the hanger detail

mounting bracke

pictorial diagram of mounting bracket

hanger band(A) hanger band(B)

Figure 24) hanging mount

9.Line and switch connection

9.1 switch installation and size (electric, automation type)

Figure 25) Switch Installation and dimensions

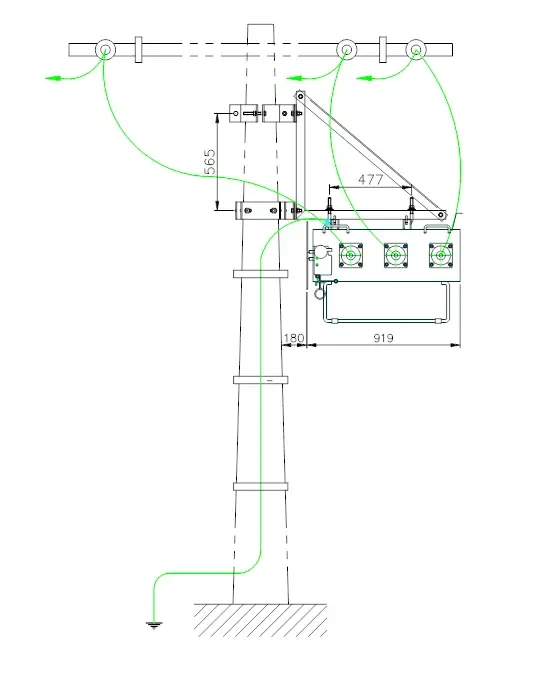

9.2 The switch hanging installation (manual type)

Figure 26) switches hanging installation

9.3 switch seat installation

Figure 27) switch mounting

10 maintenance

Manufactured products, have been adjusted to the best condition, switch maintenance, generally limited to the following conditions:

10.1 run for a certain period after the switch casing for cleaning;

10.2 within five years from the factory, due to manufacturing quality failure or leak, the manufacturer is responsible for exchange or repair (mainly around the repair or maintenance center).

10.3 SF6 gas pressure - temperature curve Cheung shown in Figure 8.

11. transport, inspection and custody

11.1 Transport

This product must be packaged transport. Transport or lifting, not allowed to have a strong vibration, does not allow inversion, rolling.

11.2 Acceptance

Acceptance in accordance with the following procedures:

11.2.1 indoors out of the box, packing list to check random files are complete;

11.2.2 Carefully remove the switch, bumps traces from the outside observation products, with particular attention to whether the porcelain sets and chipped;

11.2.3 observed gauge pressure of 0.07MPa (20 ° C) (according to user requirements to install the pressure gauge);

11.2.4 switch trial operation five times, there should be no refuse to co-and refused grading phenomenon.

11.2.5 conditions, can detect the loop resistance values (less than 130 micro-Europe).

11.3 store

This product should be stored indoors difficult to collisions and a well-ventilated place.

12.1 install and use a manual

12.2 certificate a

12.3 boxed single a

12.4 afactory inspection report

13 Ordering Information

13.1 required to determine the product type, name, number, rated current, the operating power supply type, operating voltage.

13.2 according to user requirements are available:

(A) of the terminal outlet or cable outlet;

(B) the ceramic casing and the casing of organic insulator;

(C) the special fixture connected to the bus;

(D) hanging bracket;

Send Inquiry

You may like