Dry-type Reactor

Application range

The manual applies to the installation and application of epoxy cast dry-type iron core reactor with a rating capacity of 5000Kvar or lower and the voltage level of 35KV or lower.

Classification of dry-type reactors

(1) Series reactor: installed in capacitor unit of parallel coupling and compensation and connected in series to parallel coupling capacitor to restrain harmonic current, reduce the waveform deformation of system voltage and restrain the impulse current of capacitor in circuit investment;

(2) Current-limiting reactor: connected in series to system. When system meets faults, current-limiting is used to restrain short circuit current to reduce the short circuit to the allowable value of the equipment to which short current is connected later;

(3) Parallel reactor: in over-voltage and remote transmit electricity system, parallel coupling is connected to the low voltage winding side of transformer station to compensate reactive power of long-distance light load transmit electricity line;

(4) Filter reactor: used in series with series capacitor to form resonance circuit and filter and remove specified higher harmonic;

5) Motor starting reactor: connected in series to alternating current motor to restrain starting current of motor. Reactor will be removed after the finish of starting motor;

I. Application

The product is used in power system of 35KV or lower and is connected in series to parallel capacitor to restrain the waveform deformation of the voltage of electric net so that alters the voltage quality of electric net and ensures the safe operation of power system. Harmonic current through capacitor group is restrained and close inrush current is limited to protect the safe and reliable operation of capacitor group. It applies to power system. Electric railway, metallurgy, chemical industry and patrol industry have higher requirements on fireproof. Electromagnetism interference requires installing space-limited city network transformer station.

II. Technical Features

1. Coil is made by casting with epoxy resin and has advantages such as flame retardant, self-extinguishing, maintenance free, high mechanical strength, short circuit resistance, strong shock power, great isolation strength, low partial discharge amount and long service life;

2. Iron core manufacture adopts the manufacture technology of dry-type reactor and defers in low vibration, low noise, small magnetism leakage and low electromagnetism interference to environment;

3. The product has gathering integrated structure, small installation dimension and small occupational space;

4. The technical condition of the product conforms with international standard IEC288-88 and department issuing standard JB5346-98 and the technical performance can reach the level of other same-class international products in the times;

III. The Executive Standard of CKSC Series of Resin Dry-Type Iron Core Series Reactor

IEC289-88 Reactor

GB10229-88《Reactor》

GB10229-88 Reactor

JB5346-98 Series Reactor

DL-462-92 Booking Technical Conditions of Series Reactor for High Voltage Series Reactor

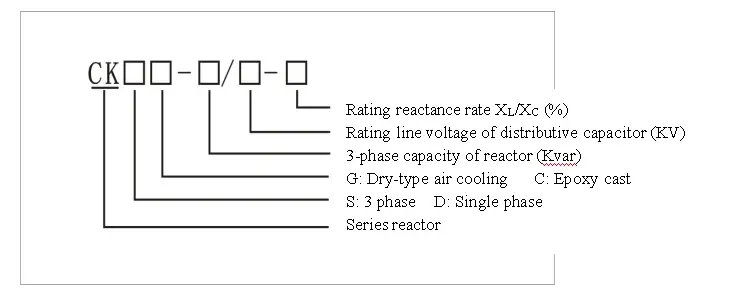

IV. The Type and Meaning of Reactor is as following:

V. Product Application Conditions

Normal application conditions of common product are that the altitude is not higher than 1,000m and environmental temperature is not higher than 40℃. If it is in excess of normal application conditions, design adjustment shall be carried out according to related regulations of GB1094, GB6450 and GB10229.

VI. Transportation and Loading and Unloading (Hoisting or Forklift Unloading) of Products

1. The transportation method of reactor to installation location is mainly road transportation or railway transportation;

2. During the transportation course of products, please pay special attention to the weather and measurements of rainproof and snow prevention shall be considered;

3. During the transportation course, the lean degree of the reactor shall be smaller than 30°;

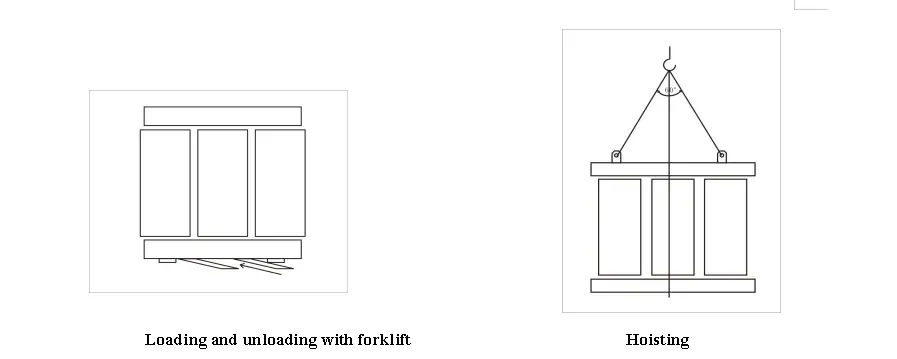

4. Four hoisting rings on clamps shall be used when reactor is hoisted and reactors with complete package shall be hoisted according to their hoisting signs (see following drawing);

5. The angle between rope and vertical line during hoisting reactor shall be smaller than 30° (see following drawing). All steel wire ropes and hooks shall bear the integrated weight of hoisting equipment;

6. The loading and unloading of products shall strictly conform to national related regulations on loading and unloading. During the whole course of loading and unloading, please pay special attention to careful unloading and balance hoisting, personnel safety and equipment safety;

7. It is forbidden to bind and drag wearable elements such as rings, insulators, cushion blocks and leads;

Loading and unloading with forklift Hoisting

VII. Storage

1. Products to store shall be stored in dry and rainproof location out of dust after receiving acceptance;

2. All products shall be stored in storeroom with package and can't be piled. Meanwhile they shall not be stored together with live chemicals and corrosive things;

3. Dry-type reactor shall not be laid outside. If short-time placement outside, dry-type reactor shall be with good package and put on wood cushion and the cushion shall be higher than 100mm;

VIII. Installation of Reactor

1. This manual shall be carefully read before installation to know the content such as outside dimension, weight and installation method of products;

2. Reactor for indoor use shall be installed in drop-prevention and sunshine-prevention room. The manufacture of reactor room shall conform with the regulations of national applicative electric regulation and architecture specification. The protective degree of reactor room shall conform with the requirements of protective level of IP23;

3. Reactor base shall bear the whole weight of reactor and conform with the requirements of national architecture specification;

4. The installation design of reactor shall conform with safety requirements of human body and shall ensure that the reactor can't be contacted by people during operation. The minimum safe distance between charged bodies and minimum safe distance between charged body and ground shall conform with the requirements of national supplied power specification. Besides the minimum safe distance between cable and high-voltage wire and minimum safe distance between temperature control wire, fan wire and high-voltage ring shall be kept. The minimum safe distance of altitude of 1,000m and lower can be seen in Table 1.

Table 1

|

Voltage level (KV) |

Maximum voltage of equipment (KV) |

Isolation level |

Safe distance (mm) |

|

|

Industrial frequency testing voltage(KV) |

Impulse testing voltage(KV) |

|||

|

3 |

3.5 |

18 |

40 |

60 |

|

6 |

6.9 |

25 |

60 |

90 |

|

10 |

11.5 |

35 |

75 |

125 |

|

15 |

17.5 |

45 |

95 |

180 |

|

20 |

23 |

55 |

125 |

225 |

|

35 |

40.5 |

85 |

170 |

340 |

5. For convenient installation, maintenance and guarding and patrol, there shall be passage between the reactor and the wall and between neighboring reactors there shall be space of larger than 1m (outrigger distance);

6. Sufficient ventilation equipment shall be ensured in reactor room to ensure that the heat produced by reactor for loss can be discharged in time. According to the cooling air requirement, discharging one Kvar of loss needs about 3m3/min of air flux. Ventilation amount is decided according to gross loss value;

7. Reactor shall be installed outside the location which is 600mmm away from the wall to ensure the surrounding air flow of reactor and personnel safety. The fence and shutter of air inlet and air outlet shall not reduce the efficient section. Air inlet and air outlet shall be designed with measurements of avoiding the entry of foreign body.

8. Generally speaking, reactor needn't to be installed with ground leg screw bolt. But if it has earthquake prevention require, it shall be installed with pre-buried ground leg screw leg according to outside dimension.

9. Before coupling all terminals to power lines, testing report and coupling diagram on the nameplate shall be understood first and the coupling shall be correct.

10. The coupling line formed by cable and bus shall conform with the regulations of operation regulation of reactor and electric installation specification. Cable and bus that is applicative to section shall be chose. Coupling line shall not produce over mechanical pull and moment on coupling terminal. When the current is over 1,000A, there shall be a piece of soft coupling between bus and reactor terminal to compensate the stress produced by conductor when heating bulge and cooling condensation happen;

11. Screw bolt coupling shall ensure sufficient contacting stress, which can apply butterfly-type cushion ring or spring cushion ring. Before coupling wires, all coupling bolts and coupling boards shall be cleaned. All coupling shall be fixed for reliably. When fix electric coupling bolt, torque wrench shall be used to make the strain of screw bolt even and avoid the production of over strain. The torque referential value subjects to Table 2.

Table 1 Reference value of screw bolt torque

|

Screw bolt dimension |

M8 |

M10 |

M12 |

M16 |

|

Torque(N.m) |

11 |

26 |

40 |

60 |

|

Torque(kgf.m) |

2 |

4 |

7.5 |

17.5 |

12. Ground screw bolts under reactor shall be connected to protective ground system. The ground resistance value of protective ground system and the section of ground wire shall conform with electric installation specification;

IX. Inspection and Testing of Reactor before Operation

1. Ring and lead connection of reactor shall be inspected whether they are loose or broke before operation;

2. Inspect all fixing screws to ensure firm and reliable;

3. Inspect whether the outside shell and iron core of reactor are permanently grounded;

4. Inspect whether there is foreign body on iron core or ring and whether there is dust or foreign body in air pipe;

Before operation, the reactor coil, core and airway should be cleaned with compressed air.;

5. Before operation, there shall be compressed air to clean the ring, iron core and air channel of the reactor;

6. Product testing before operation

6.1 Isolation resistance testing of iron core:

Let the iron core of reactor temporarily out of up clamp (recover to original position after finishing measuring) and use megohmmeter of 500V to measure (relative temperature ≤85%) iron core-clamp and ground≥2MΩ;

6.2 Isolation resistance testing of measuring ring (temperature 10℃-40℃ and relative temperature ≤85%) uses megohmmeter of 2,500V to measure the isolation resistance of winding to ground. It shall be ≥1000MΩ;

6.3 Measurement of direct current resistance

6.4 Withstanding voltage test of external industrial frequency. The testing voltage subjects to 85% of testing voltage value of finished product (see the record in the certificate manual of product). It will last one minute. See the regulation of repeated isolation testing in GB1094.3.

When test to withstanding voltage of industrial frequency is carried out to reactor with temperature control accessory, all connecting inserts of temperature control shall be pulled out before testing in case that induced voltage damages temperature control. After finishing the testing, the electricity stored in the ring of reactor shall be charged and the pulled-out inserts shall be stuck in and examined for no false. Inspect whether the temperature control wind cooling unit is installed in wrong way (see the manual of installation and application of temperature control and fan).

X. Reactor Maintenance

1. When the maintenance to reactor is carried out, safety specification shall be obeyed and reactor shall be disconnected from electric net of high voltage and electric net of low voltage;

2. The maintenance work of reactor mainly refers to remove dust, especially the dust and dirty in the air pipe, in case of blocking the cooling efficiency and reducing isolation performance. The operators can carry out the maintenance by following these orders below:

2.1 Carry out integrated outside inspection on ring, lead, temperature control unit and fan;

2.2 Removing dust can use dust collector and dry compressed air. The surfaces of isolator, terminal and other isolative parts shall be cleaned with dry cloth;

2.3 Measure isolation resistance and record the values;

2.4 Inspect whether the coupling of the power lines are firm in case that accidents happen for over heating conductor because of loose connector;

3. Inspect the firm condition of ground leg screw bolt, side tie rod and up and down tie rod and tighten in time if they are loose;

XI. Safety Requirements

1. The testing, installation and maintenance of reactor shall be done with qualified specialists and carried out according to safety specification of electric equipment;

2. Reactor that needs to be installed with outside shell, cover shall be set. The space between the cover and reactor shall be larger than the safety distance (see Table 3). During the operation of reactor, warning notice board written with "electric danger" shall be hung. The warning notice shall conform with related regulation of GB2894-88R;

Table 3

|

Voltage level(KV) |

10KV and less |

20 |

35 |

|

Safety distance(m) |

0.4 |

0.6 |

0.6 |

3. After starting operation of the reactor, contacting the reactor body (including the line surface) is forbidden in case of electric shock happening.