SF6 gas density monitor

1:An SF6density monitor warns operators of dropping levels that indicate contamination and/or leaks.

SF6 density monitors are temperature compensated and hermetically sealed to shield measurements from atmospheric pressure fluctuations and differences in mounting level.

2: SF6 density relay is widely used in the high and middle voltage switching power electric appliance industry. The product takes the advanced technology of the same industry at home and abroad, and has a unique advanced temperature compensation function. The product can detect and control the inner density of SF6 gas of the high and medium voltage switches and electrical equipment, to ensure the normal operation of the equipment, prevent the equipment from being damaged by the leakage of SF6 gas, and play a protective role for the equipment.

3: Product Advantages:

1). The product adopts all stainless steel, exquisite appearance, small in size.

2). The contacts are gold-coated, with high opening and closing power and low contact resistance.

3). The junction box adopts plug-in type, convenient wiring, reliable and stable.

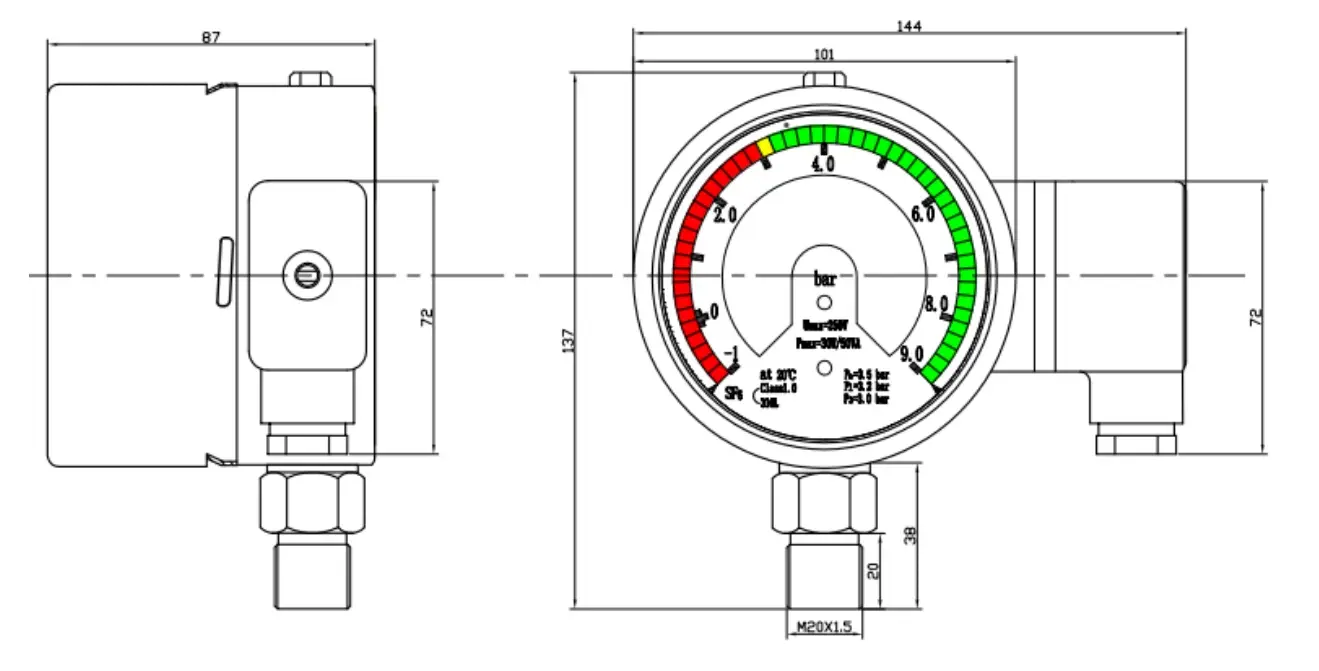

4: Main technical parameters

1). Measuring range: -0.1-0.9Mpa.

2).Precision level: 1.5(at 20℃), 2.5(at -30℃~60℃)

3). Connector thread: M20*1.5 (can be supplied according to user requirements)

4). Ambient temperature: -30-60℃, atmospheric pressure 86-106Kpa.

5). Relative humidity: ≤95﹪.

6). Protection grade: IP65

7). Impact resistance: 300 m/s2

8). Shock resistance: 20m/s2

9). Insulation strength: AC2500V/1min 50Hz.

10). Insulation resistance: more than 500M.

11). Annual air leakage rate: not more than 10-15Mpam3/s.

12). Contact capacity: 30VA. Maximum working voltage: AC 380V.

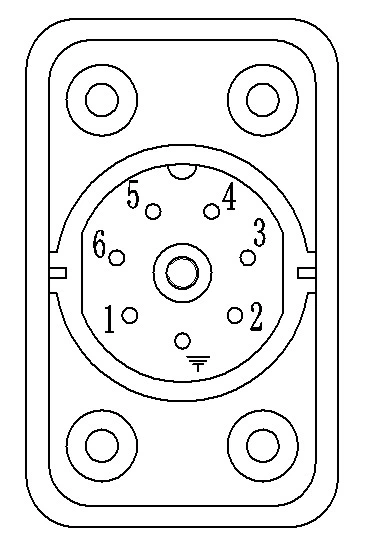

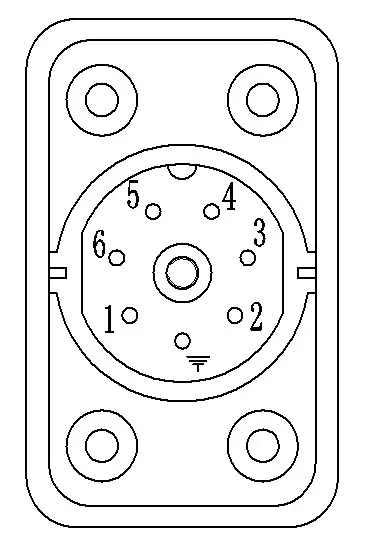

13). Wiring signs:

1 2 Alarm pressure value

3 4 Blocking pressure value

5 6 Blocking pressure value

5:. Corresponding rated pressure, alarm pressure, blocking pressure value for production, commonly used specifications are shown in the table below (can be produced according to user requirements):

Checking and storage

1)After receiving the product, the user should check the box first, if there is any damage, should identify the reason immediately.

2)Take out the product when opening the box and check whether it is good and whether the product certification is complete, if there is any damage, please notify the factory immediately.

3)Store the product in a dry and ventilated place, the storage temperature is 0~40℃ relative humidity ≤80%, the indoor air should not contain the medium that causes a corrosive effect on the product.

External Dimensions