CD17

1,Overview

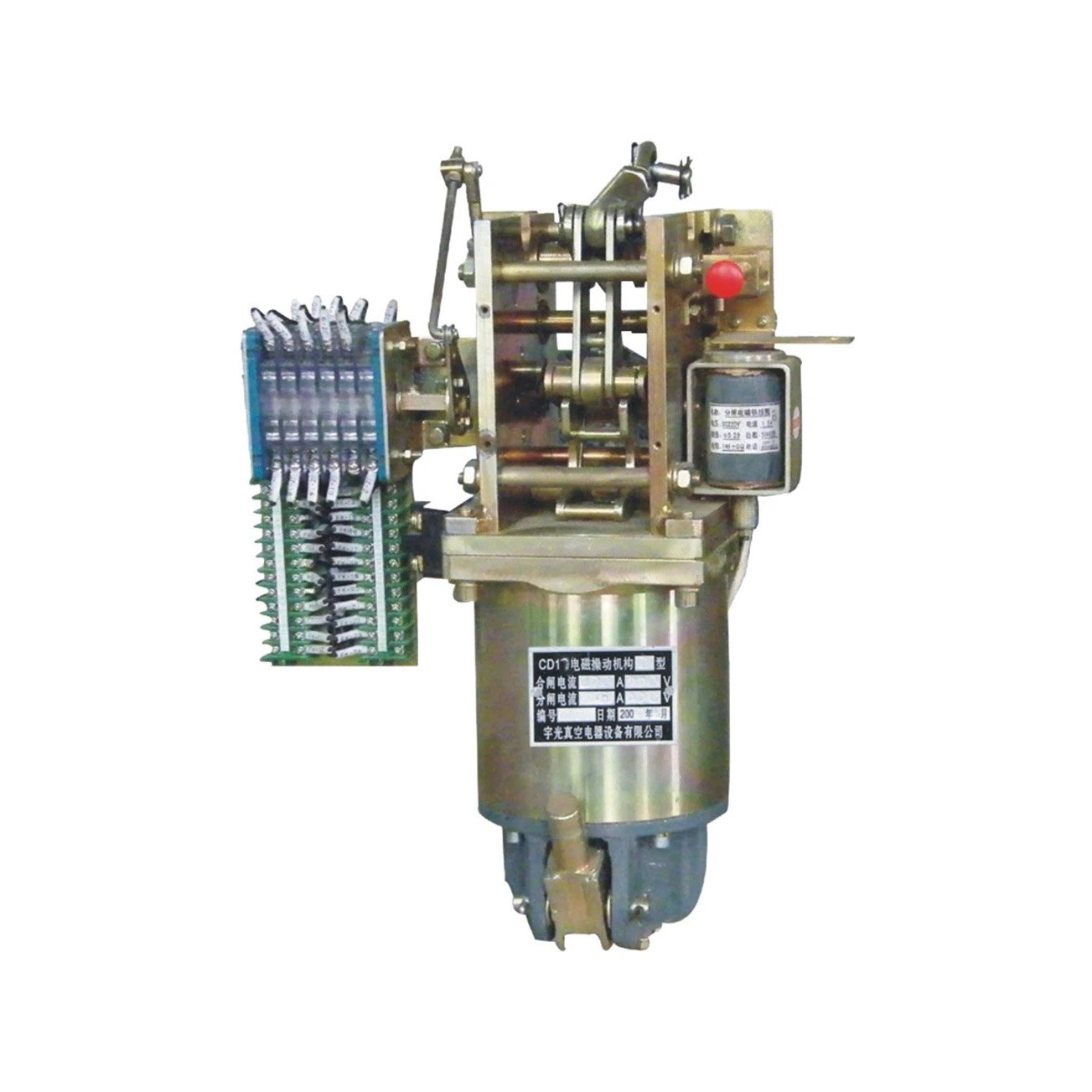

CD17 and CD17B type DC electromagnetic actuator is mainly used to actuate ZN28-12 series indoor high-voltage vacuum circuit breakers and other frequently operated vacuum circuit breakers.

CD17 type electric actuator is used to actuate all kinds of indoor high-voltage vacuum circuit breakers on the trolley cabinet;

CD17B type electric actuator is used to actuate all kinds of indoor high-voltage vacuum circuit breakers on the stationary cabinet, and the electric actuators of this series can operate by using a DC power supply, which can operate electric closing and splitting manually with indoor vacuum circuit breaker and automatic reclosing. DC power supply, with indoor vacuum circuit breaker, can carry out electric closing and splitting, manual splitting, remote control splitting and automatic reclosing operations, and its performance is in full compliance with GB1984 "AC High Voltage Circuit Breaker" and the requirements of the technical conditions of the product.

2,Use of environmental conditions

The ambient temperature is not higher than +40℃ and not lower than -15℃. Altitude not exceeding 1000m.

Relative temperature not more than 90% (+25℃)

There is no fire, explosion danger, serious filth, chemical corrosion or violent vibration in the place.

3,Main technical parameters

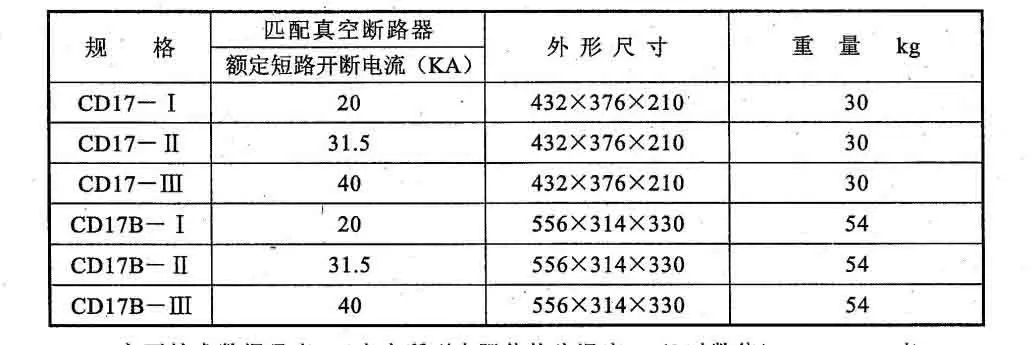

1). The main matching of the organisation is shown in Table 1 Table 1

. The main technical data are shown in Table 2 (the resistance values listed in the table are the values when the temperature is +20℃) Table 2

|

Specification |

Closing coil |

Opening coil |

|||

|

|

|

Current(A) |

Resistor(Ω) |

Current(A) |

Resistor(Ω) |

3). The coil of the mechanism is short-time working system, and its operating power supply is DC.

4). The reliable closing voltage of the mechanism is 85%~110% of the rated operating voltage. The reliable breaking voltage is 65%~120% of the rated working voltage, and the mechanism can not be opened when it is less than 30% of the rated working voltage.

5). between the conductive part and the grounding part, between the conductive part of different circuits. 1min frequency withstand voltage 2500V, there should be no flashover and breakdown phenomena. Coil turn-to-turn withstand 2.5 times the rated operating voltage.

6). The working angle of the output shaft of the mechanism is 50°~55°, and the life of the mechanism is 10000 times.

4. Brief description of structure and principle of operation

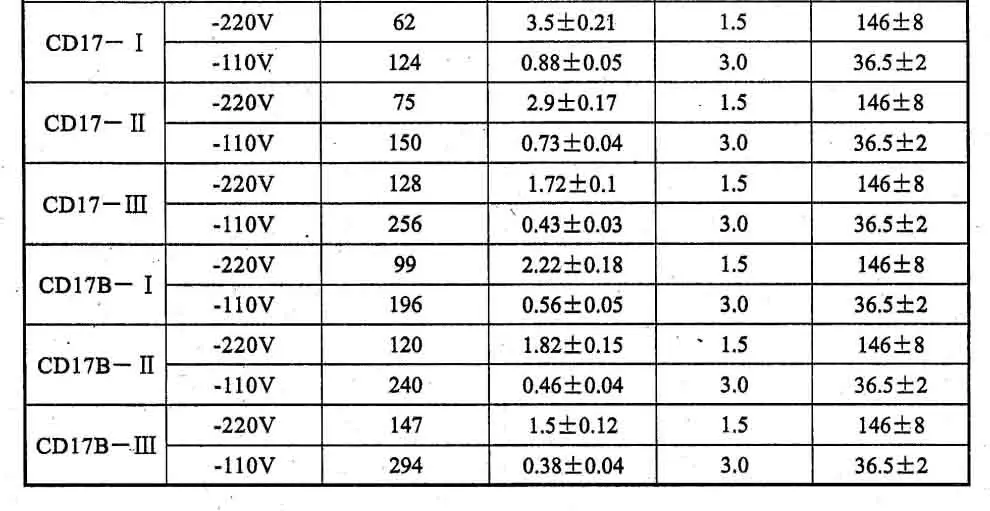

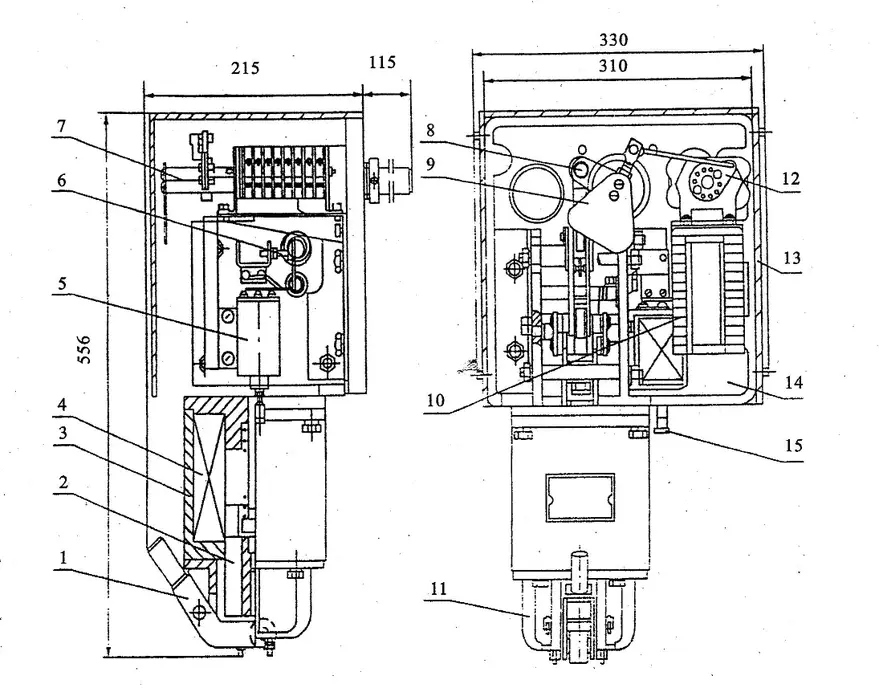

1). The outline of CD17 type electric manipulator is shown in Fig. 1, and the outline of CD17B type electric manipulator is shown in Fig. 2.

1. Closing handle 2. Closing core 3. Magnetic yoke 4. Closing coil

5. close brake electromagnet 6. Opening pushbutton

7. Adjustment screws 8.Auxiliary switch 9.Terminal block

10.Base 11. Closing indication

Figure-CD17 Outline

CD17B type electric actuator is improved and perfected on the basis of CD17 type electric actuator with reference to the transmission mode of CD10 type electric actuator. The performance and main technical parameters of CD17B type electric actuator are basically the same as those of CD17 type electric actuator. In order to make the CD17B type electric manipulator can be installed in the fixed cabinet panel for operation, in the CD17 type electric manipulator mounting bracket added a base frame to change the direction of the output drive shaft.

1.Closing handle 2.Closing core 3. magnetic yoke 4.Closing coil

5. close brake electromagnet 6.Adjustment screw 7.Shaft

8.Turning arm 9.Closing indication 10.Terminal 11.Base

12.Auxiliary switch 13.Housing 14.Bracket 15.Switching movement core

Figure 2 CD17B outline

3. The installation holes of CD17B type electric manipulator in the cabinet are the same as those of CD10 type electric manipulator in terms of dimensions.

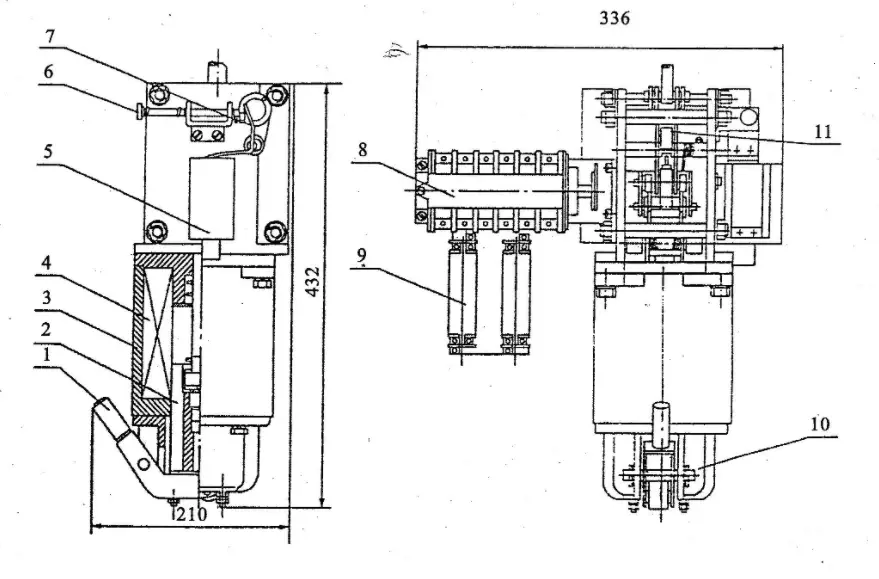

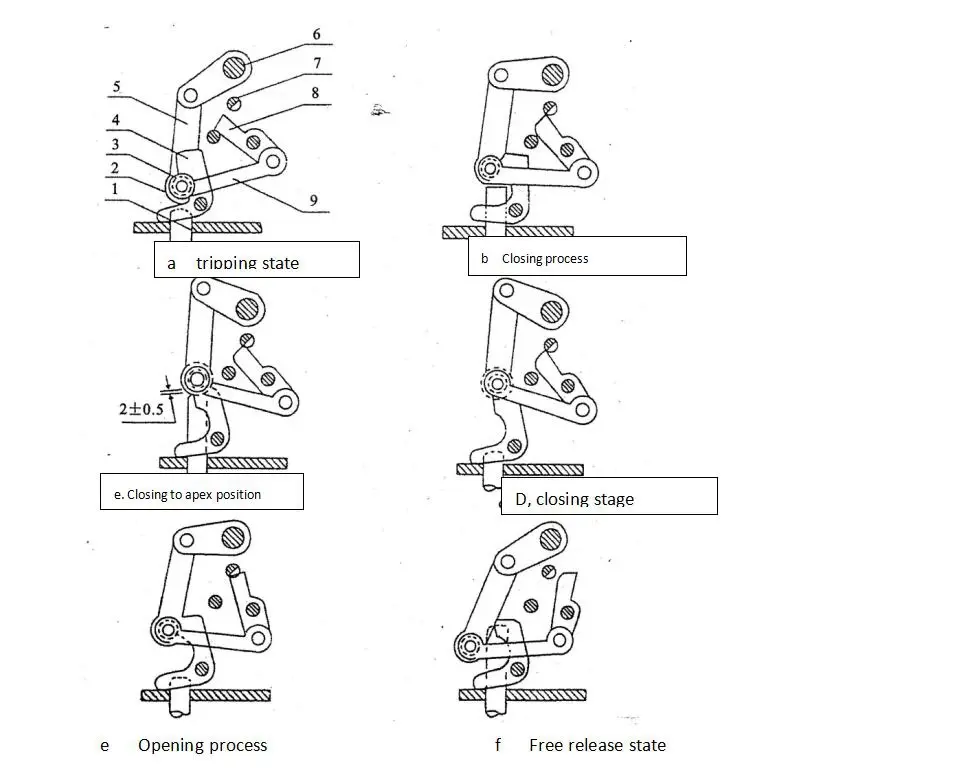

4. The principle of action and the operating mechanism of the opening and closing state and the free release state are shown in Figure III.

(1) Closing action process

Before closing, the switch 8 is in reset state (Fig. 3a), after the closing coil is energized, the core pushes 2 so that the switch 8 is buckled with the half-axis 7, and the core pushes the wheel 2 upward, which drives the output shaft 6 to rotate about 50°~55° through the connecting rod, and through the output top lever, the circuit breaker closes (Fig. 3b), at this time, the circuit breaker breakers spring is stretched and stored, and the contact spring is compressed. When the core rises to the end, the set 3 (dotted line in the figure) button 4 appears 2 ± 0.5mm gap (Figure IIIc). At this time, because the spindle rotation, drive auxiliary switch, so that the closing circuit normally closed contacts open, cut off the closing coil power supply, the core falls, set 3 by the button 4 support, complete the closing action (Figure 3d).

When the tripping coil is energized, or when the tripping is done by hand, the half-axis 7 rotates in the clockwise direction, the switch 8 is unbuttoned with the half-axis 7, so that the sleeve 3 leaves the switch, and the output shaft 6 rotates in the counterclockwise direction under the joint action of the tripping spring and the contact spring to complete the tripping action, and at the same time drives the auxiliary switch, so that the normally-closed contacts in the tripping circuit are opened and the power supply to the tripping coil is cut off (Fig. 3e).

(3) Free release action process.

During the closing process, the closing iron core top wheel 2 upward movement, once followed by the opening instruction, the opening iron core start, so that half-axis 7 and button 8 unbuttoning, under the action of the opening spring and contact spring, wheel 2 from the closing iron core top bar 1 end slides down, and realize the free debut (Figure III f).

5. The internal wiring diagram of the CD17 type CD17B electrical operating mechanism is shown in Fig. IV.

1.Top lever 2.Wheel 3.Sleeve 4.latch 5.Connecting rod

6.Output shaft 7.Half shaft 8.Valve 9.Connecting rod

Figure 3 State diagram

Wiring Diagram Diagram 4

FK-F11-11I/W Auxiliary Switch

TQ-Trip coil

HQ-Closing coil

JZ, HZ, - terminal block

HA-Closing button

HA-Closing button

HC-Closing contactor

HD-red signal lamp

LD-Green signal lamp

Note:

1. The circuit breaker is in the open position.

2. ② ④ delay time normally closed

3. Dotted line in the box for the organization of the wiring, the rest of the line for reference

Installation and adjustment 5,

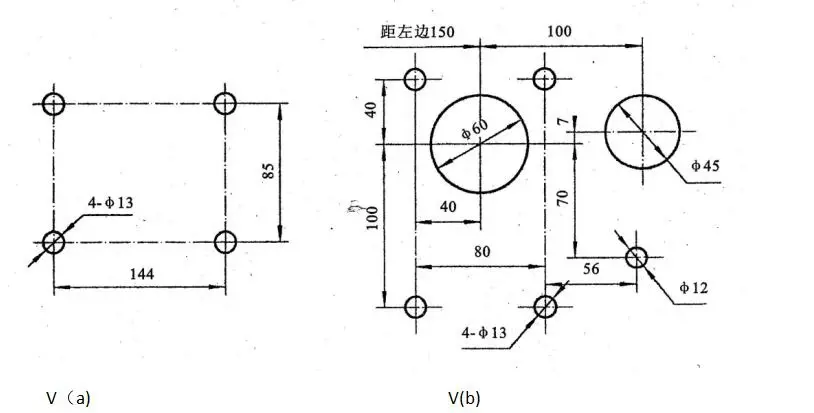

1. See Figure V(a) for mounting dimensions of the CD17 type electric actuator.

See Figure V(b) for installation dimensions of CD17B type electric actuator.

Remarks.

1: Φ60 holes are holes for the transmission main shaft, Φ45 holes are holes for the inlet, and 4-Φ13 holes are mounting holes.

2.CD17 type DC electromagnetic actuator mechanism is generally used with ZN28-12 vacuum circuit breaker and other indoor high-voltage vacuum circuit breaker, users can adjust the length of the output linkage according to the need.

3. mechanism and circuit breaker installation, should be used first closing handle, hand force slowly close the gate, check whether it is card, phenomenon of closing iron core top lever to the apex position, the gap between the button and set should reach 2sh 0.5mm. closing iron core should be flexible movement without stagnation.

4. after the assembly of mechanism and circuit breaker, the angle of connecting plate of auxiliary switch and the length of connecting rod of mechanism and auxiliary switch should be adjusted, so that the auxiliary switch is accurately in place at the position of closing and closing, and there is no hysteresis phenomenon.

5. Adjust the snap depth of the button and half shaft so that the snap depth is 1.5~2.5mm.

6. After the debugging of hand force closing, then carry out motorized opening and closing within the working voltage range, operate 5 times, it should be reliable, otherwise it should be re-adjusted. (Note: The rated voltage is the end voltage of the coil).

7. The switching coil is designed according to the short-time working system, and the continuous operation of electric switching should not be more than 10 times during the commissioning, and the interval between each operation should not be less than 5S, in order to prevent the coil from being burnt.

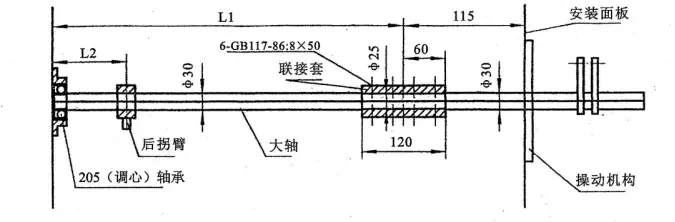

8. In addition to the above, special attention should be paid to the rotational flexibility of the output drive shaft when installing the CD17B type electric manipulator. After connecting the drive shaft, it is not allowed to have the phenomenon of jamming and lagging. See Figure 6 for specific installation.

Remark.

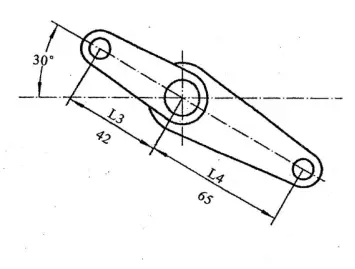

L1 is the length of user-made drive shaft.

L2 is the distance from the back of the arm to the back of the high-pressure cabinet.

L3 is the center distance of the output arm on the mechanism.

L4 is the center distance of the rear arm. The status shown in the figure is the closing position.

Figure 6 Drive Shaft Installation Schematic

Use and Repair

1. Before use, you should check whether the data marked on the nameplate is consistent with the actual use, especially whether the power supply voltage is consistent.

2. Rated operating procedure: "minute-0.3S a close minute-180S a close minute".

3. When the mechanism is in operation, it is sometimes found that after the closing coil is energized, the closing core does not reach the closing end position set 3 is not held by the switch and returns to make the circuit breaker open. At this time, the closing signal is not removed, the closing coil is again energized, the core and immediately close a gate, so rapid continuous closing several times, known as: "jump" phenomenon. The reason is:.

a. Half-axis 7 and button 8 between the amount of buckle is too small, buckle. At this time should be adjusted to adjust the screw 6, so that the amount of fastening in 1.5 ~ 2.5mm. Take out the core, adjust the height of the top bar of the core, so as to meet the clearance requirements.

b.. Whether the button has the phenomenon of stagnation, or the gap between the button and the set does not meet the requirements of 2士0.5mm,if it exceeds this requirement, the base should be removed, take out the core, adjust the height of the core top lever, so as to make it meet the gap requirements.

c. The closing coil is cut off prematurely by the auxiliary switch to close the power supply, at this time, the length of the auxiliary switch lever should be adjusted to make the circuit breaker close reliably.

4. The disassembled and overhauled actuator should be checked according to the steps of installation and commissioning, and it can be put into operation only after it is qualified.