I. Purpose

SF6 remote density relay ("relay") is mainly used to control and monitor the density of SF6 gas in sealed container. They are generally used in SF6 high voltage switches, medium voltage switches, gas insulated systems (GIS), high voltage cables, transformers and mutual inductors, and are suitable for harsh outdoor environments. The relay has two or three sets of mechanical contacts, and used to send information to the target equipment terminal through the contact connection circuit when the pressure reaches the state of alarm, blocking or overpressure. At the same time, the relay is also equipped with a safe and reliable circuit transmission function, to realise real-time data remote reading and information monitoring to establish an effective platform. It can transmit pressure, temperature, density and other information to the target device (usually a computer terminal) in a timely manner. The target device will analyse the data and control the corresponding terminal action.

SF6 remote density relay is an organic combination of mechanical and electronic, in order to ensure the safety of mechanical contacts, and will be effective data in time through the current or RS485 form of transmission to the target equipment. The target device can read the density and other information in the table in real time, the data transmission adopts 4-20MA or RS485 way, to ensure the integrity and accuracy of the data. The combination of electronic and mechanical data transmission to the equipment terminal, reliable and safe for the terminal equipment to make timely and effective control to lay a solid hardware platform. SF6 remote density relay with reliable mechanical contacts and safe electronic remote transmission combined, it will become a powerful tool for electronic monitoring industry.

II. Features:

1. Stainless steel fully enclosed shell, good waterproof and anti-corrosion performance, beautiful appearance.

2. The gas density signal can be transmitted over a long distance.

3. The temperature sensing element is made of imported materials , high precision and stable compensation performance.

4. Control and indication are integrated.

5. Oil-free design, vibration-resistant, shock-resistant performance is excellent.

6. Adopting imported, unique contact device design, real high-performance electric contact.

7. Electronic remote transmission using bus form, reduce the number of line connection.

8. Density using 4 ∽ 20mA or RS485 signal transmission, suitable for long-distance transmission.

9. Mechanical and electronic organic combination, the total transmission of data, so that the data is safe and reliable.

III. Technical Parameter:

1.Measuring range: Relative pressure: -0.1-0.9Mpa. Absolute pressure: 0 -1.0Mpa.

2. Precision level: 1.5 level (20 ℃), 2.5 level (-30 ℃ ~ 60 ℃)

3. Shell protection grade: IP65

4. Sealing performance: ≤ 1.0×10-9Pa-m3/s

5.Working power supply: DC24V

6. Impact resistance: 500m/s2

7. Anti-vibration performance: 200 m/s2

8. Contact capacity: AC / DC 250V 1000VA/500W

9. Ambient temperature: -30-60℃, atmospheric pressure 86-106Kpa.

10. Relative humidity: ≤95﹪.

11. Insulating strength: AC2500V/1min 50Hz.

12. Insulation resistance: ≥500M.

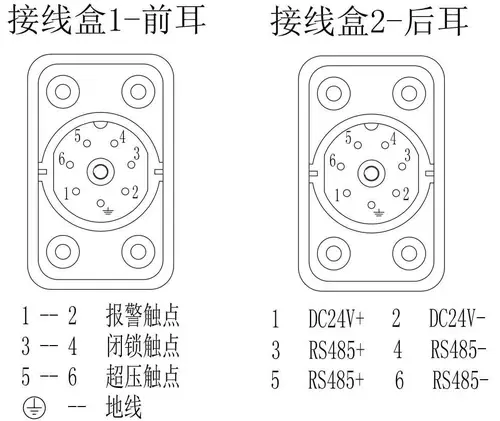

13. Wiring sign

Junction Box 1 Front Ear Junction Box 2 Back Ear

|

1-2 Alarm contact 3-4 Latching contact 5-6 Overpressure contact --Ground |

IV. EMS, EMC Performance Indicators:

1. El 1. Electrostatic discharge immunity according to the standard GB/T 17626.2 severity level 4

2. Immunity to radio frequency electromagnetic field radiation according to GB/T 17626.3 severity level 3

3. Electrical fast transient pulse group immunity according to GB/T 17626.4 severity level 4

4. Surge/shock immunity according to GB/T 17626.5 severity level 4.

5. Conducted nuisance immunity according to GB/T 17626.6 severity level 3.

6. Magnetic field immunity according to GB/T 17626.8 severity level 5.

7. Impulse magnetic field immunity according to GB/T 17626.9 severity level 5.

8. Magnetic field immunity to damped oscillations according to GB/T 17626.10 severity level 5.

V. Installation and use

1. The remote SF6 density relay must be installed vertically on the equipment interface, the shell on the explosion-proof cap non-pro fessionals are prohibited open, to prevent changes in the atmospheric pressure of its inner cavity from affecting the accuracy of the product.

2. When installing the equipment valve switch off, disassemble the original equipment density relay using a dust-free cloth, alcohol or wet na pkin to deal with the surface clean. Sealing ring apply sealing grease. Must be fixed with a spanner in the joint part of the tightening nut.

3. The relay should be raised and down slowly to prevent damage to the relay.

4. When the relay is not in use, the temperature compensation is in non-temperature compensation equilibrium state, the pointer

changes with the ambient temperature, the temperature is higher than 20 ℃, the pointer is lower than the 0 position line. When the

temperature is lower than 20℃, the pointer is higher than the 0 position line. When the ambient temperature deviates from 20℃, the

pointer deviates about 0.02 Mpa for every 10℃. When the relay is filled with SF6 gas of rated pressure value, the relay will work on the

relative value of SF6 gas density and pressure at 20℃.

VII.Guide for Order

1. When ordering, please specify the instrument model, rated pressure, alarm pressure, blocking pressure, connector thread and whether it

is filled with silicone oil.

2. Please specify the special requirements in the contract or settle by agreement.

3. The corresponding values of rated pressure, alarm pressure and blocking pressure will be produced, and the common specifications are

shown in the table below (can be produced according to customer's requirements):

|

Rated pressure (Mpa) |

Alarm pressure (Mpa) |

Locking pressure (Mpa) |

|

0.35 |

0.30 |

0.30 |

|

0.35 |

0.32 |

0.30 |

|

0.36 |

0.32 |

0.32 |

|

0.38 |

0.34 |

0.30 |

|

0.40 |

0.30 |

0.30 |

|

0.40 |

0.32 |

0.30 |

|

0.40 |

0.35 |

0.30 |

|

0.40 |

0.35 |

0.35 |

|

0.45 |

0.42 |

0.40 |

|

0.50 |

0.42 |

0.40 |

|

0.50 |

0.45 |

0.40 |

|

0.55 |

0.48 |

0.45 |

|

0.60 |

0.52 |

0.50 |

|

0.60 |

0.55 |

0.50 |

|

0.62 |

0.59 |

0.54 |

|

0.65 |

0.62 |

0.59 |

VII. Inspection and Custody

1. After receiving the product, the user should check whether the box is intact and immediately identify the reason for the damage.

2. Open the box and take out the product to check whether it is complete, and the product certification manual is intact, if any is damaged, please immediately notify our factory.

3. Store the product in a dry and ventilated place, the storage temperature is 0~40℃, relative humidity≤80%, the indoor air shouldn't contain the medium causing corrosive effect to the product.

SF6 Remote Density Relay Appearance Schematic Figure

VIII. On-site installation cases:

OEM/ODM Services:

At Shaanxi Yuguang Electric Co., Ltd., we understand the importance of customization. That's why we offer comprehensive OEM and ODM services to meet your specific requirements. Whether you need private labeling or custom product development, our experienced team is here to assist you every step of the way.

Certificates:

We take pride in our commitment to quality and safety. Our products are certified to meet the highest industry standards, including:

3C Certification

ISO 9001 Certification

21 Utility Model Patents and Design Patents

Why Choose Us:

State-of-the-art Manufacturing Equipment

Extensive Testing Facilities

Comprehensive Quality Assurance Processes

ISO 9001 Certified Quality Management System

One-year Warranty on All Products

Large Production Capacity

FAQ:

Q: What is the warranty period for your products? A: We offer a one-year warranty on all our products.

Q: Can you customize products according to our specifications? A: Yes, we provide OEM and ODM services to meet your specific requirements.

Q: Are your products compliant with international standards? A: Yes, our products meet all relevant international standards.

Q: What is the lead time for orders? A: The lead time depends on the quantity and customization requirements. Please contact us for more information.

Q: Do you provide technical support? A: Yes, we offer comprehensive technical support to our customers.

Packaging:

Wooden Box Packaging

Carton Packaging

Foam-filled Packaging

Waterproof and Moisture-proof Packaging

Customized Packaging

International Standard Packaging

Logistics:

Sea Freight

Air Freight

Land Transportation

Multimodal Transport

Express Delivery Services

Contact Us:

Ready to take your electrical projects to the next level? Contact us today at ygvcb@hotmail.com to discuss your requirements and explore partnership opportunities with Shaanxi Yuguang Electric Co., Ltd. Let's create a brighter future together.