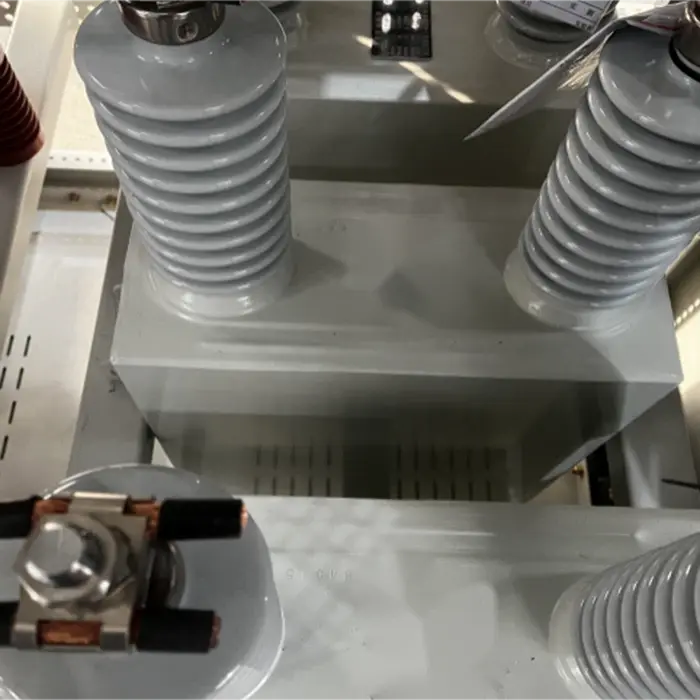

High voltage shunt capacitor

Content

1 , Capacitor designation and type …………………………….………...

2 , Main technical parameters & main technical performance targets ……..

3 , Main structures ……………………………………………………..

4 , Lifting, acceptance, preservation and installation ……………………..

5 , Test before running ………………………………………………….

6 , Protections …………………………………………………………..

7 , Connect and disconnect……………………………………………...

8 , Discharge of capacitor ……………………………………………….

9 , Maintaining and Troubleshooting ……………………………………

10 , How to determine the capacity of capacitor …………………………..

This manual is applicable to shunt capacitor, which is used in AC power system (50/60Hz, rated voltage is above 1kV). This sort of capacitor mainly provide reactive power for AC power system, to improve power factor, reduce losses, improve voltage quality and fully achieve efficiency of power generator.

The high voltage shunt capacitor produced by Shaanxi Yuguang Electric Co., Ltd.has excellent performance and reliable quality. The developments, designs, manufactures and tests are in strict compliance with the International Electro-technical Commission Standards IEC60871-1.1997, National Standards GB/T11024-2010 and Power industry Standards DL/T840-2003. And some parameters are above the requirements of those Standards.

1 Capacitor's designation and type

1.1 Capacitor's designation is high voltage shunt capacitor

1.2 Capacitor type's representation

In this figure ![]() expressed in Chinese Pinyin Capital letters △ expressed in Arabic numbers

expressed in Chinese Pinyin Capital letters △ expressed in Arabic numbers

1.2.1 Series number:

B means shunt capacitor

1.2.2 Medium code

FM-fully film dipped by PXE or PEPE

AM-fully film dipped by C101 oil 1.2.3 The 1st feature code means rated voltage, in kV.

1.2.4 The 2nd feature code means rated capacity, inkvar.

1.2.5 The 3rd feature code means phase quantity, 1 for single phase, 3 for tri-phase (internal Y- connection), 1 ×3 for Single-phase connection, each phase is isolated

1.2.6 The code at end, W means capacitor can be used outside

G means capacitor can be used on plateau

For example, BAM12-334-1W

Means shunt capacitor, fully film dipped by C101 oil, rated voltage is 12kV, and rated capacity is 334kvar, single phase, can be used outside.

The symbol on index tag

---means capacitor has discharge resistance,![]() means capacitor has internal fuse.

means capacitor has internal fuse.

2 Main technical parameters & main technical performance targets

The technical parameters and performance of capacitor are based on the order. The main content of the parameters and performance will be given on the product plate. The following gives the general performance.

2.1 The capacitor should be used in the ambient air temperature between -40 ℃ and +45 ℃ places, and the sea level should be not higher than 1000m. The product with the code 'G ' at end can be use in the place whose sea level can be higher than 1000m. If the users have special demand they shall particularly describe in the order.

2.2 The capacitance error of the capacitor does not exceed the rated value of -3% ~ +5%. In three-phase capacitor the ratio measured between the maximum and minimum capacitance in any of the two line terminals is not more than 1.05 in 200 kvar capacitor and below, and is not more than 1.02 in capacitor with bigger capacity.

2.3 Under 20℃,rated frequency and rated voltage, the capacitor loss tangent value shall comply with the following provisions:

It is no more than 0.0003 in dipping all film capacitor with discharge resistance and internal fuse; and is no more than 0.0002 in the capacitor without discharge resistance and internal fuse.

2.4 The electric strength of dielectric

The dielectric between capacitor terminals should sustain one of the following test voltages for 10s.

A ,2.15 Un AC voltage with working frequency. Un means rated voltage. B ,4.3Un DC voltage

To three-phase capacitor the test voltage should be adjust to ensure that every phase can sustain the above voltage value.

2.5 The capacitor is permit to run for 8 hours every 24 hours under the voltage no more than 1.1Un and even can be used under 1.15Un (except instant over voltage) for 30 minutes in every 24hours. But in order to prolong the capacitor's life, it should often be kept using under no more than rated voltage.

2.6 The capacitor could be used under 1.3In (In means rated current), which is caused by voltage rise or high-order harmonic. To the capacitor with the maximum capacitance error, the over current is permit to reach 1.37In. if capacitor is used under

no more than 1.1Un, the voltage including all harmonic components should be no more than 1.2·![]()

![]() 2 Un.

2 Un.

Note: the rated current of capacitor is the Sine wave current that flows through the capacitor of rated capacity with rated voltage and frequency.

2.7 Mechanical strength of the capacitor bushing and conducted stick

2.7.1 Welding bushing

A The bushing of the capacitor whose capacity is below 200kvar shall sustain horizontal force for 400N.

B The bushing of the capacitor whose capacity is between 200kvar and 1000kvar shall sustain horizontal force for 500N.

C The bushing of the capacitor whose capacity is above 1000kvar shall sustain horizontal force for 900N.

D The Torque that the conducted stick sustains shall correspond with the demand of table 1.

Table 1

|

Conducted stick Screw thread |

Torque to nut spanner (N ·M) |

|

|

Maximum value |

Minimum value |

|

|

M10 |

10 |

5.0 |

|

M12 |

15 |

7.5 |

|

M16 |

30 |

15 |

|

M20 |

52 |

26 |

2.7.2 Pressing -jointing bushing

A The capacitor bushing can sustain static pull of 1500N, which parallels with the axis of the bushing;

B The capacitor bushing can sustain static pull of 1000N, which is Perpendicular to the axis of the bushing;

C ,The maximum value of the torque to nut spanner is 40N ·M;

2.8 When the capacitor with internal discharge resistance is disconnected with power source, it could decrease the voltage from summit value to 75V in 10 minutes. The user shall particularly describe in the order, if they want it to decrease the voltage from summit value to 50V in 5 minutes.

3 Main structures

3.1 The main components of capacitor

3.1.1 The capacitor is mainly consisted of container and device body. And the device body is consisted of the core and insulation wrapper which is wrapped outside the care. The container is full of liquid medium for dipping. The core is consisted of several elements and insulation parts. The element is rolled, pressed and made of two aluminum foils and some piece of thin dielectric polypropylene films sandwiched between the two aluminum foils. In order to reach the different demand of voltage and capacity, the elements in core is connected by some series and parallel method. The technology of aluminum foil edge folding and protruding welding are used to reduce the loss and increase the performance of partial discharging.

In the capacitor with internal fuses, every element has a piece of fuse, which is series connected with it. When the element is broken down, other elements in parallel can discharge to it at once and can blow the fuse in few milliseconds. That ensure the broken element be removed immediately. If the change of capacity is no more than 5%, the capacitor can still keep running.

3.1.2 the container is welded of thin steel plate or stainless steel plate. The container can compensate the volume change of internal liquid medium caused by the change of temperature. There are bushings on the cover of container, and on the side of the container there are two rings for lifting, moving and installing. On one of the rings there is a earthing-bolt, with the figure ![]() (Some capacitor units have feet at the bottom for installing).

(Some capacitor units have feet at the bottom for installing).

3.2 The three-phase capacitor of 6kV ,10kV have Y type connection or independent terminal leading. Every phase has discharge resistance.

4 Lifting, acceptance, preservation and installation

4.1 Lifting

4.1.1 In order to avoid damaging, when the capacitor is lifting for long distance, it must have package. And there must be some pads between capacitors and between the capacitor and the inner wall of the package to avoid directly impact.

4.1.2 When carrying, the capacitor should be placed vertically (the bushings are put upward). Moving the bushing is forbidden when the capacitor unit is moving. When the capacitor is moved in the package, the worker should pay attention to the upward signal ' ![]() '

'

4.2 Acceptance

4.2.1 When the users get capacitor, they should check the appearance at first. Check the container, bushings, conducted stick, earthing- bolt and so on. And also check the accuracy of the index tag and the container whether it is leak. The ambient temperature of capacitor installing and running should be in accordance with the temperature category of the capacitor. The rated voltage of capacitor must be not less

than the maximum voltage of the power system that it would connect in. The voltage rise caused by the capacitor joining in is consideratetoo. When the series reactor is

connected in system to inhibit the harmonic wave and the inrush current, the voltage between capacitor terminals will be higher than the power system running voltage. Sounder this situation, the users shall choose the higher rated voltage capacitor.

4.2.2 When checking if the users want to re-measure the capacitance, they should measure by the methods those relative error are less than 2%.

4.3 Preservation

4.3.1 The capacitor should be persevered in the place which could avoid rain, snow, and be without corrosion gas or steam. The air temperature should comply with the range of clause 2.1. Avoid hot source damage and dust falling on the capacitor directly.

4.3.2 When preserving, the capacitor shall be put vertically and keep the bushing upward. It is forbidden to put one capacitor unit on another without any support.

4.4 Installing

4.4.1 The capacitors of every series shall be fixed in the place that has no erosive steam, gas, no conductance and explosiveness dust. And the place shall be ventilated well.

4.4.2 The capacitor can be fixed on the iron frameworks in single row of double row. When the capacitor is fixed vertically, the layer quantity from bottom to top should not more than 3. The distance between each layer shall be enough long for insulation. The distance between each capacitor shall be more than 50mm. The capacitors can also be flat fixed. In order to be ventilated and inspected conveniently by worker, the complete equipment shall have maintaining channel, and its width shall be more than

1.2m.

4.4.3 Installing the level clapboard between layers shall NOT be allowed, because it would affect air circulation. The outlet of cool air shall be installed above the capacitor banks.

4.4.4 Before fixing capacitors on framework, it shall be trimmed in order to balance the capacitance between phases. The ratio between the maximum and minimum among the phases shall not more than 1.02. The ratio between the maximum and minimum among the serial sections shall not more than 1.01.

4.4.5 The capacitors shall be connected with flexible wire. It shall use two wrenches (preferably torque wrenches) to approaches from the upper and lower. The index tag shall be place outwardly, so the worker can inspect comfortably.

4.4.6 The voltage waveform and characteristics of the line shall be determined after the capacitor is installed and take some relevant measures especially to the line that have harmonic source such as electric commutator.

4.4.7 Besides above, the following subject shall also be considered:

4.4.7.1 The capacitor is directly connected at the outlet terminal of induction motor, when the motor is cut off from the line, it maybe make self excitation. So the voltage on capacitor is likely to rise even over the rated voltage. To avoid this, when choosing capacitor, the capacitor's rated current must less than 90% electric motor no-load current.

4.4.7.2 When the current is bigger than the specification of clause 2.6, the capacitor must be stopped. The trouble maybe caused by the following issues:

A The shunt capacitor bank is connected in the system. The ultraharmonics can make resonance and harmonic wave bigger. So before connecting, check whether the capacity of capacitor bank is near the resonance capacity. If it is near, some relevant measure shall betaken.

B The harmonic component is too big.

The electric-arc furnace, silicon control installation, transformer core saturation are the main source of the harmonic wave. If the current of capacitor is bigger than the specification of clause 2.6, it must be stopped at once until the situation is improved by some measures.

There are some suggestions

A Move part or all the capacitor unit to another system.

B Add current-limiting reactor

C Add filter on the side of harmonic wave source load.

5 Test before running

5.1 Before using, the new capacitor or the capacitor stopped using for longtime could betaken voltage toleration test for 5s~10s. the test voltage value is shown in table 2 (measure voltage on test product). The capacitor with single bushing could only be taken voltage toleration test between electrodes. Before and after test, shall measure the capacitance. Ifthe change is apparent, the capacitor should not be used.

5.2 It should take the method that can avoid error caused by harmonic wave to measure the capacitor loss tangent value under the voltage of 0.9~1.1Un. The measurement accuracy shall be not less than 20%, and the result shall comply with the specification of clause 2.3.

6 Protections

6.1 the capacitor bank shall be protected by some measures, such as Unbalanced differential voltage, Neutral unbalance current, Bridge differential current, Open delta voltage protection, Short- delay over-current, Short circuit quick break between buses and over-current or over-voltage relay protection, etc. To the capacitor of 3.15kV and above, every capacitor unit need a fuse protector to protect it which shall comply with relevant standards. The fuse protector shall sustain the inrush current when the capacitor is connecting. The top value of the inrush current shall be not more than 100In. The rated current of the fuse protector is 1.5~1.6 times the rated current of protected capacitor to prevent capacitor container from explosion.

6.2 Besides above, the following protection could betaken in necessary situation.

6.2.1 If the rise of voltage is regular and for long time, take some measures to limit it not to exceed the specification of clause 2.5.

6.2.2 When the capacitor bank is connected with over-ground cable, it can take suitable lightning arrester to get atmospheric overvoltage protection.

6.2.3 In high-voltage power networks, when the ground short-circuit current is over

20A, and the protection device or fuse protector cannot take short-circuit protection to ground reliably, it shall have ground short-circuit protection device for single phase.

7 Connect and disconnect

7.1 Use the Meg-ohmmeter to measure the dielectric resistance of capacitor bank , before it is connected. The resistance value shall be more than 5000M Ω.

7.2 The following shall be considered when the capacitor bank is connected or disconnected.

7.2.1 It is forbidden to connect the capacitor bank with power networks, when the voltage of collecting bar is over the maximum allowed values of the specification of clause 2.5.

7.2.2 It is not allowed to re-connect the capacitor bank with power networks at once after it is disconnect with the networks until the voltage on capacitor bank terminals is no more than 10% rated voltage.

7.2.3 The rated current of high-voltage circuit-breaker that is used to connect and disconnect capacitor bank shall be not less than 1.5 times the rated current of the capacitor bank. Moreover it shall choose no-repeated breakdown high-voltage circuit-breaker. To high-voltage circuit-breaker that need to remove the short-circuit fault, its rated breaking current shall be bigger than the short-circuit current at the mounted position.

7.3 Check before commissioning

7.3.1 Check whether the connection of capacitor bank is correct and the installing complies with the demands.

7.3.2 Check whether the connection of accessory is correct and the installing complies with the demands.

7.3.3 Check whether the debugging and setting of accessory comply with the technology demands.

7.3.4 The capacitor shall have protection to avoid miss-operation and ensure personal safety.

8 Discharge of capacitor

8.1 The capacitor bank must have discharging device. The device shall auto-discharge after capacitor is disconnect with the networks and reduce the top value of the capacitor rated voltage to 50V or below in 5s.

8.2 In order to protect capacitor bank the auto discharging device shall be parallel connected with capacitor directly (without switch and fuse protector between them). The capacitor that is connected with motor directly could have no discharging device.

8.3 Before touch the current-carrying part of the capacitor that is disconnected with the power networks, it still must take the metallic pole with insulation to short-circuit the capacitor terminals and ground, even the capacitor has self-discharged and be confirmed uncharged. After that the worker can be close to the capacitor.

9 Maintaining and Troubleshooting

9.1 Maintaining

9.1.1 Record the conditions of capacitor running.

9.1.2 When the installation is running, it should be inspected regularly. If the container faces of capacitor expand for more than 15mm (for 100kvar or above) or 10mm (for below 100kavr) or any other anomalies happened, the installation should be stopped, andre-run after finding out the reason and fixing it.

9.1.3 Take the idle-current wattmeter to check the load of each phase of the capacitor bank.

9.1.4 The temperature when the capacitor bank is put in: the capacitor that takes C101 and PEPE oil as liquid medium shall not lower than -40℃; the capacitor that takes S oil as liquid medium shall not lower than -25℃. The top limit temperature when running: category A is +40℃ and B is +45℃, every 24 hours the average temperature is no more than +30℃ for category A and +35℃ for B, and the annual average temperature is no more than +20 ℃ for category A and +25℃ for B. If the temperature exceeds the limit, the capacitor shall be cool by fan or other method, or disconnected with the power networks.

9.1.5 Use infra-red thermometer to measure the hottest point of the installing site and the container capacitors, and record the result (especially in summer).

9.1.6 When running the working voltage and current cannot be more than the specification of clause 2.5 and clause 2.6.

9.1.7 Connecting the capacitor with the power networks would raise the networks voltage. If the voltage between the capacitor terminals is more than 1.1Un, all or apart of the capacitors shall be removed from the networks.

9.1.8 Prevent the surface of the bushings, the containers and the frameworks from dust or other dirt.

9.1.9 Pay more attention to all the connection point in the circuit such as bus-bar, earthing cable, switchers and breakers. Ensure their connection is reliable. Because a error connection, even a nut is not tight enough, can cause the whole installation to fault.

9.1.10 if the user wants to make voltage sustaining test or measure capacitance for the capacitor after it runs a year, the result is refer to table 2.

9.1.11 Check the capacitance and fuse protector for at least once for every year. And also measure the loss tangent. These measurement or test shall be carried on at rated voltage or almost rated voltage

9.1.12 When the tripping operation caused by actuating of relay is happening, it is forbidden to re-switch on before the reason is found. When checking, cut the power for 10 minutes first, and then switch on the earthing switch after electricity check. After all the inspection, remove the earthing cable and switch off the earthing switch.

9.1.13 if the container is leak in transportation or moving, the user can use braze welding with half-and-half solder to fix it.

9.2 Troubleshooting

9.2.1 The users can fix the following trouble by themselves on site.

9.2.1.1 If the container is leak, the user can use braze welding with half-and-half solder to fix it.

9.2.1.2 If the welded joint of the bushing is leak, can use braze welding with half-and-half solder to fix it. But be careful that, the soldering iron shall not be too hot. Because it would lose weld the silver lay. If the pressing - jointing bushing is leak, it must be carried back and fixed by manufacturer.

10 How to determine the capacity of capacitor

10.1 Set load power is P, power factor before compensating is cosφ1 , the power

factor that need to be is cosφ2 ,and the required capacity is Q. It can be calculated as the following formula

(kvar)

(kvar)

In this formula:P-S×cosφ1

S-Rated apparent output of load

Q- When the load power factor is cosφ1 and cosφ2 , we can get the kvar value that needed by each kW load from table 3, and then multiply it by P to get the required capacity.

For example :cosφ1 =0.6 ,cosφ2 =0.9,we can get the kvar value is 0.85 that

needed by each kW load from table 3. If the load power P is 100kW, we get the required capacity Q=100×0.85=85kvar.

Note: This manual is the general manual for capacitor, so the product type including product capacity, weight, etc and special product are not included. The special demands of individual products are shown in the dedicated manual for those capacitor product.

Attachment:The definition of capacity for three-phase capacitor (Y-connection inside)

C = ![]() (C1-2 + C2-3 + C1-3)

(C1-2 + C2-3 + C1-3)

Table 2 Test voltage for capacitor(AC 50Hz) Table 2

|

Insulation level of capacitor (kV) |

1 |

3 |

6 |

10 |

20 |

|

Between terminal and ground (kV) |

5 |

19 |

23 |

32 |

49 |

|

Between terminals(times) |

1.61 Un |

||||

Note :Un--Rated voltage of capacitor

Table 3

|

power factor before compensating cosφ1 |

In order to reach cosφ2 , the kvar value for each kW load |

||||||||||||

|

0.70 |

0.75 |

0.80 |

0.82 |

0.84 |

0.86 |

0.88 |

0.90 |

0.92 |

0.94 |

0.96 |

0.98 |

1.00 |

|

|

0.30 |

2.16 |

2.30 |

2.42 |

2.48 |

2.53 |

2.59 |

2.65 |

2.70 |

2.76 |

2.82 |

2.89 |

2.98 |

3.18 |

|

0.35 |

1.66 |

1.80 |

1.93 |

1.98 |

2.03 |

2.08 |

2.14 |

2.19 |

2.25 |

2.31 |

2.38 |

2.47 |

2.68 |

|

0.40 |

1.27 |

1.41 |

1.54 |

1.60 |

1.65 |

1.70 |

1.76 |

1.81 |

1.87 |

1.93 |

2.00 |

2.09 |

2.29 |

|

0.45 |

0.97 |

1.11 |

1.24 |

1.29 |

1.34 |

1.40 |

1.45 |

1.51 |

1.56 |

1.62 |

1.69 |

1.78 |

1.99 |

|

0.50 |

0.71 |

0.85 |

0.98 |

1.04 |

1.09 |

1.14 |

1.20 |

1.25 |

1.31 |

1.37 |

1.44 |

1.53 |

1.73 |

|

0.52 |

0.62 |

0.76 |

0.89 |

0.95 |

1.00 |

||||||||