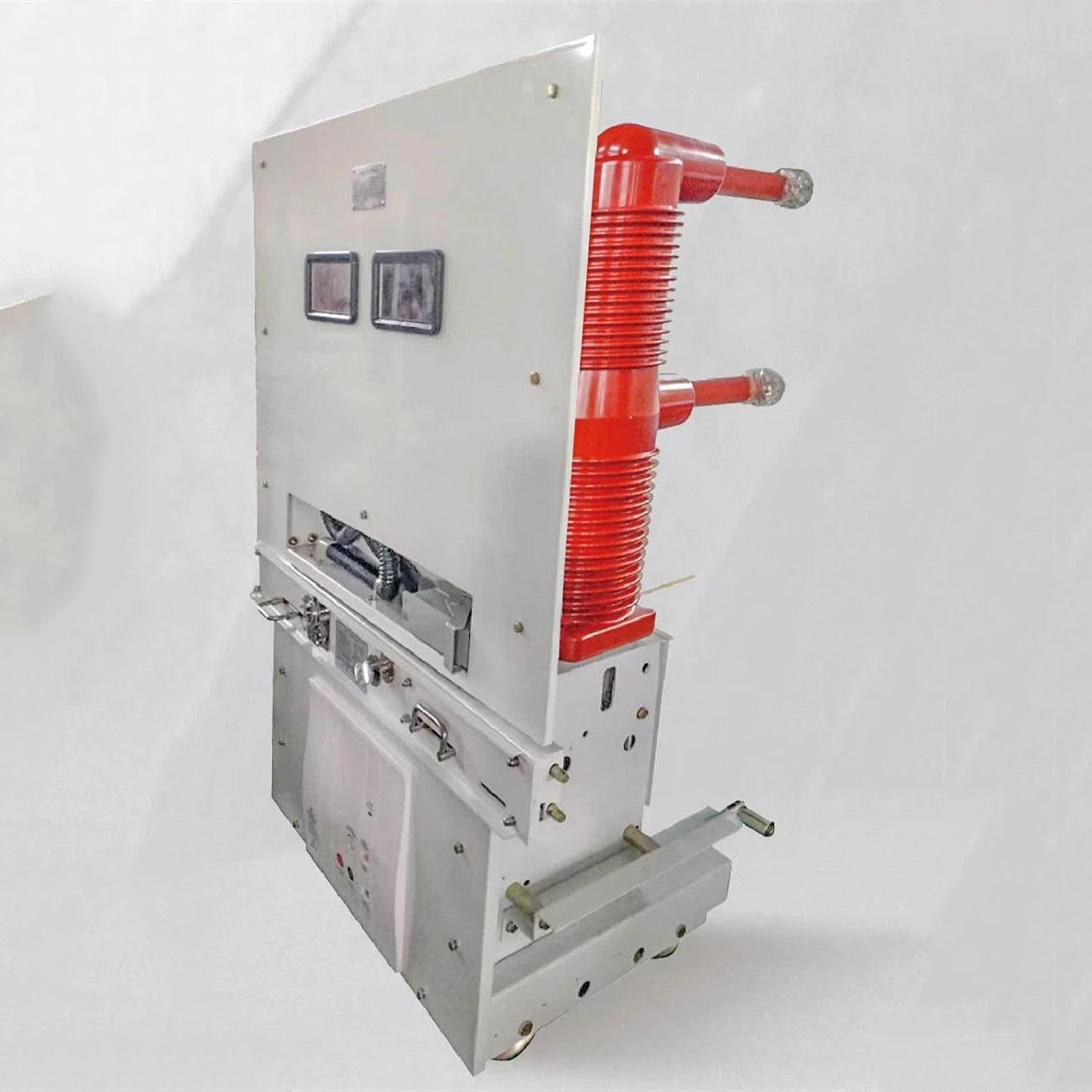

YGM-40.5 Permanent Magnets Vaccum Circuit Breaker

- Free Samples

- Quality Assurance

- 24/7 Customer Service

Product Introduction

Ⅰ. Overview:

YGM-40.5 permanent Magnets vaccum circuit breaker is suitable for three-phase AC 50Hz, 40.5kV system, for industrial and mining enterprises, power plants and substations as the load current, overload current, fault current, and suitable for frequent operation occasions.

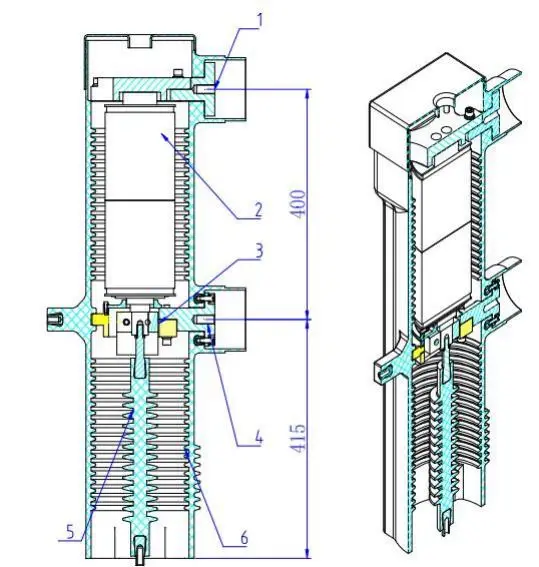

1.The drawing inside permanent mechanism

2. Main uses, scope of application and environmental conditions of the

product

1). Circuit breaker is suitable for three-phase AC 50Hz, 40.5kV system, for industrial and mining enterprises, power plants and substations as the load current, overload current, fault current,

and suitable for frequent operation occasions.

2). Environmental Conditions:

a) Ambient air temperature does not exceed 40℃, the average daily temperature does not exceed 35℃; The minimum ambient air temperature is -15℃.

b) The average daily relative humidity does not exceed 95%; The average daily steam pressure does not exceed 2.2kPa; The average monthly relative humidity is less than 90%; The average monthly vapor pressure does not exceed 1.8kPa.

c) The altitude is not more than 1000m.

d) The surrounding air is not significantly contaminated by dust, smoke, corrosive and/or flammable gases, vapors or salt spray.

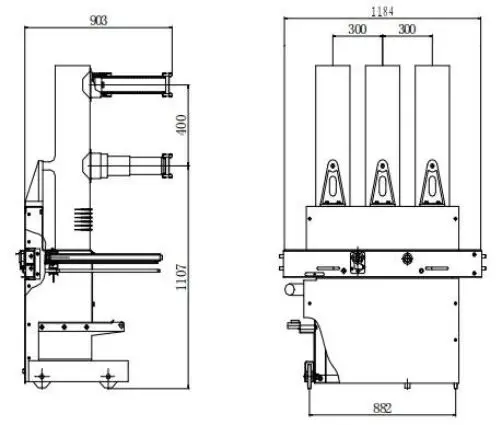

3. Product outline and installation dimensions are shown in Figure 1:

fig1: Circuit breaker outline drawing

4. Technical Specification:

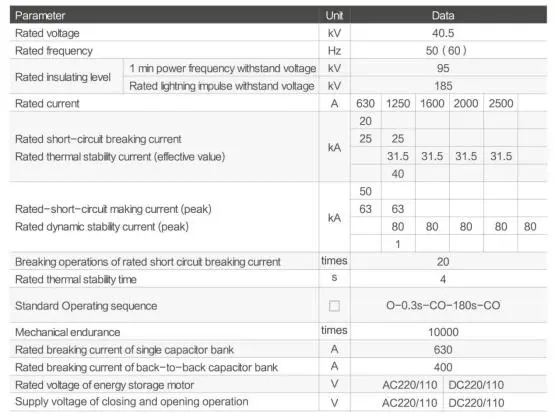

1). Circuit Breaker Table sheet 1:

Table 1

|

Project |

Unit |

Specification |

|

Rated Current |

kV |

40.5 |

|

1min Industrial frequency withstand voltage (RMS) |

kV |

95 |

|

Lightning Impact Withstand Voltage (Peak) |

kV |

185 |

|

Rated frequency |

Hz |

50 |

|

rated current |

A |

1250 ,1600 ,2000 |

|

Rated short-time withstand current |

kA |

31.5 |

|

Rated peak withstand current |

kA |

80 |

|

Rated short circuit duration |

s |

4 |

|

Rated short-circuit breaking current |

kA |

31.5 |

|

Rated short-circuit closing current |

kA |

80 |

|

Rated sequence of operation |

O-0.3s-CO-180s-CO |

|

|

on-off time |

ms |

<80 |

|

Rated short-circuit breaking current breaking times |

time |

20 |

|

Individual capacitor bank opening current |

A |

630 |

|

Back-to-back capacitor bank opening current |

A |

400 |

|

Rated operating voltage |

V |

-110/~ 110, -220/~220 |

|

mechanical life |

time |

10000 |

2). Technical Parameters as below:

Ⅱ. Structure and working principles

1. Structure

The circuit breaker adopts the up and down arrangement structure, which effectively reduces the depth of the circuit breaker.

The circuit breaker adopts a composite insulation structure, and the three-phase interrupter

and the connected live body are isolated by three independent epoxy resin insulating enclosures. After the composite insulation structure is adopted, the circuit breaker can meet the

requirements of air clear distance and creep distance under normal operating conditions. The volume of circuit breaker is reduced effectively. The main electric circuit vacuum interrupter and the dynamic and static conductive connection are installed in the insulation cylinder, so that the pole spacing is 300mm. The main circuit electrical connections are all fixed connections, with high reliability. The insulation cylinder is mounted on the circuit breaker frame.

The operating mechanism adopts a permanent magnet operating mechanism and is installed in the circuit breaker frame. Its structural characteristics are more suitable for the upper and

lower layout of the circuit breaker, and become an integral part of the overall structure of the

circuit breaker. The design of the mechanism is simple, and the output curve matches well with the requirements of the arc extinguishing chamber. Its performance is more suitable for the

characteristics and requirements of 40.5kV vacuum circuit breaker.

The overall layout of the circuit breaker is reasonable, beautiful, simple, small size, flexible

operation, has the characteristics of reliable electricity, long service life, easy maintenance, and less maintenance of the mechanism, which is suitable for a variety of occasions and workplaces with harsh operating conditions.

2. Working Principle

1). Electrical working principle

The main electrical circuit is shown in Figure 2: The vacuum interrupter is the core component of the vacuum circuit breaker breaking current. The vacuum interrupter used in this circuit

breaker is a newly designed vacuum interrupter with a middle seal structure inside the main shield, and the diameter and length of the pipe are significantly reduced. A series of research tests show that the new vacuum interrupter has good breaking ability and insulation

performance, and the breaking current is 31.5kA.

When the circuit breaker receives the opening instruction, the moving contact of the arc

extinguishing chamber is separated from the static contact at a certain opening speed under the drive of the mechanism, and the cutting current of the vacuum arc extinguishing chamber

completes the opening operation.

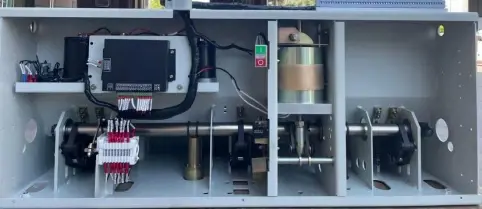

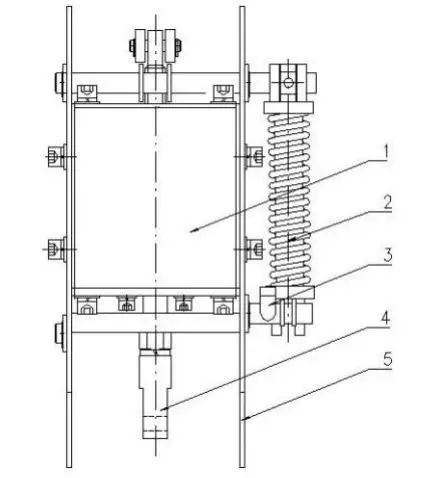

2). Structure of the operating mechanism

Circuit breaker part adopts modular design, which mainly includes permanent magnet

operating mechanism, manual emergency opening module, controller module, energy storage module. The configurations of permanent magnet operating mechanism and manual emergency opening module are shown in Figure 3. The permanent magnet mechanism adopts double coil mono-stable form. Compared with the conventional operating mechanism of the circuit breaker, the number of parts is reduced by 80%, with the reduction of the number of parts, the probability of failure is reduced, and the reliability is further improved. Easy to intelligent control and operation. The emergency manual opening device adopts the opening spring to realize the opening operation.

3. Working principle of mono-stable permanent magnet mechanism

When the permanent magnet operating mechanism is closed in the circuit breaker, there is no current flowing through the coil. Due to the action of the permanent magnet, the moving iron

core remains at the upper end. When the switch is opened, the current in a specific direction is passed through the operating coil, and the magnetic field in the opposite direction of the

permanent magnet field is generated at the upper end of the moving iron core, so that the

magnetic force of the moving iron core is reduced. When the upward force of the moving core is less than the tension of the contact spring, the moving core moves downward to realize the

opening of the permanent magnet mechanism. When the operating coil is in the opening

position, a current in the opposite direction of the opening operation is passed through the

operating coil. This current generates a magnetic field in the same direction as the permanent magnet magnetic field in the upper part of the static iron core, and a magnetic field in the

opposite direction of the permanent magnet magnetic field in the lower part of the moving iron core, so that the magnetic attraction force on the lower part of the moving iron core is reduced. When the operating current increases to a certain value, The upward electromagnetic force is greater than the suction and spring reaction force at the lower end, and the moving iron core moves upward to achieve closing.

4. Characteristics of permanent magnet controller

The circuit breaker adopts a permanent magnet mechanism controller, which has the following characteristics:

1) . Auxiliary switch position detection.

2). Flexible value setting. Through the communication interface can be conveniently set: control pulse limit time, closing in place delay, control voltage undervoltage value.

3). Intelligent communication interface. The device has an intelligent communication interface, which can complete the three-remote function and meet the requirements of intelligent electrical equipment.

4). Anti-interference capability in line with international standards. The controller can withstand EMI tests such as class IV fast transients, surge, impulse withstand voltage, etc., and has strong on-site working ability.

5. Energy storage module of permanent magnet mechanism

The energy storage module adopts capacitor energy storage, which has the characteristics of short energy storage time and long service life, and its service life can be up to 10 years at 30 °C.

Fig.2 Main electrical circuit diagram

Note :

1. Upper conductive block 2. Vacuum Arc chamber 3. Soft connection 4. Lower conductive block

5. Operate the insulator 6. Insulation cylinder

Permanent magnet operating mechanism

1.Mono-stable operating mechanism 2. Manual opening mechanism 3. Hand parting handle

4. Mechanism output shaft 5. Mechanism mounting plate

Fig 3. Mechanism diagram

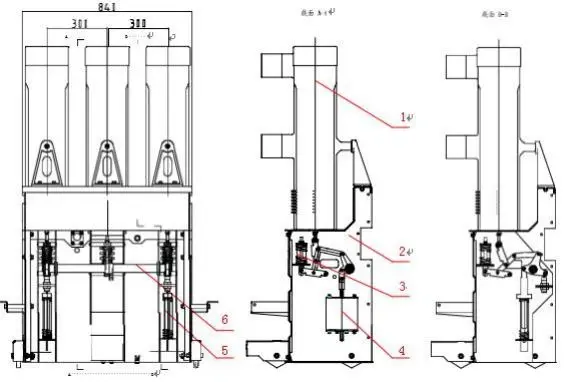

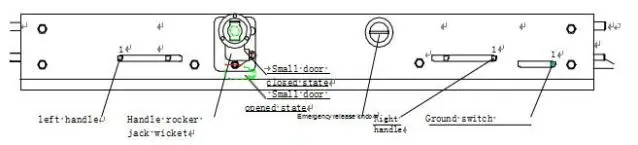

6. Advancing mechanism

Adopt screw and nut drive to push forward and withdraw the circuit breaker, see Fig. 5.

1). Push forward: when the circuit breaker is in test position and in tripping state, open the small door (the left and right handles of the rocking mechanism and the interlocking operation handle of the earthing switch need to be in position 1), insert the rocker, rock the circuit breaker to the working position, remove the rocker and close the small door, then the circuit breaker can be

opened and closed.

2). Exit: When the circuit breaker is in the working position and in the tripping state, open the

door (the left and right handles of the rocking-in mechanism and the interlocking operating

handle of the earthing switch need to be in place), insert the rocker, rock the circuit breaker to

the test position, remove the rocker, and close the door before the circuit breaker can be opened and closed.

Fig. 4 Structure of Circuit Breaker

|

Figure: 1 pole 2 frame |

3 contact spring |

4 permanent magnet mechanism |

|

5 Breakout spring |

6 Major shaft |

Fig. 5. Promoting institutions

Ⅲ. Installation and adjustment

1. Inspection before installation

After the circuit breaker is unpacked, check whether the components are complete, whether the circuit breaker is damp or damaged, and whether the operation is normal according to the packing list. After checking, clean the surface of the circuit breaker. Check the vacuum degree of the vacuum interrupter chamber with the frequency withstand voltage method (the circuit

breaker is opened, and the frequency 95kV/1min is applied at the breakout). After all checks are qualified, the installation can be carried out.

2. Adjustment

Unpacking check intact products generally do not need to re-commissioning, only when found that the circuit breaker does not meet its technical requirements or replacement of important

parts, the need for product commissioning.

First of all, adjust the vacuum interrupter dynamic conductive rod under the rod end of the

joint bearings and oil buffer height, so that the vacuum interrupter contacts open distance of 20 ± 2mm; so that the contact contact stroke of 7.5 ± 1.5mm; and then check the major axis of the various parts of the joints and oil buffer is normal. Finally, adjust the mechanism so that the

mechanism moves normally, no matter manual or electric control, the actions of closing and closing should not be stagnant.

After the overall adjustment of the circuit breaker is completed, it should meet the requirements of the parameters listed in Table 2.

Table 2

|

No. |

Description |

Unit |

Parameters |

|

1 |

Contact opening distance |

mm |

20±2 |

|

2 |

Over-travel |

mm |

7.5±1.5 |

|

3 |

Allowable contact wear thickness |

mm |

3 |

|

4 |

Average closing speed |

m/s |

0.65±0.15 |

|

5 |

Average opening speed |

m/s |

1.6±0.2 |

|

6 |

Bouncing time of contact closing |

ms |

≤3 |

|

7 |

Three-phase contact closing non- synchronous |

ms |

≤2 |

|

8 |

Three-phase contact opening non- synchronous |

ms |

≤ |

|

9 |

Split contact bounce amplitude |

mm |

2 |

Ⅳ.Use and Troubleshooting

1. The rated operating sequence of the circuit breaker is:

Minute-0.3s-Close Minute-180s-Close Minute

The opening and closing operation of the circuit breaker allows two types of operation: electric operation and manual operation.

1). Motorized operation

After the secondary plug of the circuit breaker is connected with the external control circuit, the opening and closing of the circuit breaker can be remotely controlled by the closing coil.

2). Manual operation mode

Insert the hand-opening bar into the hand-opening hole to operate the circuit breaker manually.

2. Troubleshooting

When there is a malfunction of unknown cause or the malfunction cannot be handled, please contact the manufacturer for maintenance.

Ⅴ. Maintenance

1. Circuit breakers in operation shall be inspected periodically, and the inspection shall include:

a) Check the vacuum interrupter chamber vacuum;

b) Check whether the contact stroke and contact opening distance meet the requirements;

c) Check whether the fasteners are loose;

d)Check whether the circuit breaker is dry and clean.

e) Check the auxiliary switch contacts for ablation.

2. After the circuit breaker is found to be damp, all the insulating parts should be inspected in time; the parts which have been damp should be dried in the oven at 70~80℃ for 48 hours and then reassembled and debugged until they meet the parameter requirements in Table 2.

3. Every 2000 operations should be checked for each part of the mechanism, found loose, poor lubrication, timely correction.

4. Arc extinguishing chamber open fault current 20 times, should check the vacuum of the arc extinguishing chamber, contact burns, if not meet the requirements, then replace the arc

extinguishing chamber.

5. Use and maintenance process, it is strictly prohibited to use hard objects (such as tools) to hit the vacuum arc extinguishing chamber shell.

Ⅵ. Transportation and storage

1. The circuit breaker shall not be tipped over and subjected to strong vibration or rain during transportation.

2. When the circuit breaker is not used for a long time, it should be coated with industrial petroleum jelly on the conductive surface.

3. Circuit breakers should be stored in a ventilated and dry room, placed vertically and not stacked.

Ⅶ. Random documents

1. Product certification

2. Installation and use instructions

3. Packing list

Ⅷ. Ordering instructions

1. Ordering should be indicated:

a) Model, name and quantity of the product purchased.

b) Operating voltage.

c) Name and quantity of spare parts.

Ⅸ .Appendix

1. Inspection Reports

IIX Price as following as reference:

Embedded pole trollery $9928 /pcs

Fixed type(close to 3AH4) $8571/pcs FOB SHANGHAI

Send Inquiry

You may like