ⅠProduct Description:

Ⅱ ZN85-40.5 type indoor vacuum circuit breaker using environment.

1. Ambient temperature not higher than +40℃, not lower than -25℃ (storage and transport at -30℃ is allowed);

2. The altitude is not greater than 1000m;

3. The average relative humidity of the air is not greater than 95%, the average daily value of saturated vapour pressure is not greater than 2.2×10Mpa, and the average monthly value is not greater than 1.8×10Mpa; condensation is possible when the temperature drops sharply during the high temperature period;

4. Earthquake intensity does not exceed 8 degrees;

5. No fire, explosion, serious pollution, chemical corrosion and severe vibration places.

Ⅲ ZN85-40.5 type indoor vacuum circuit breaker main technical parameters.

Fixed Removable circuit breakers:

Split type with permanent magnet mechanism electromagnetic coil technical parameters:

|

Name |

Voltage |

Item |

Unit |

MCD-I |

MCD-Ⅱ |

MCD-Ⅲ |

|

20 kA |

25 kA/31.5 kA |

40 kA |

||||

|

Closing Coil |

DC220V |

Operating current |

A |

63 |

80 |

100 |

|

Resistance (20℃) |

Ω |

4.4±0.22 |

3.15±0.17 |

2.2±0.11 |

||

|

Opening Coil |

DC220V |

Operating current |

A |

2.5 |

||

|

Resistance(20℃) |

Ω |

88±4.4 |

||||

|

AC operation |

AC170-260 |

Input Current |

A |

0.6 |

||

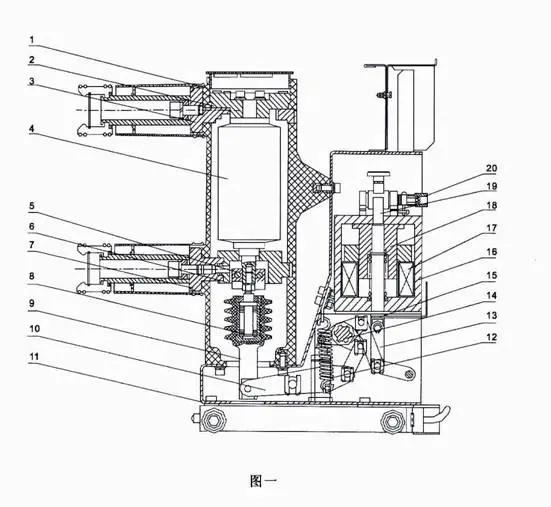

ⅣFixed, removable circuit breaker product structure and working principle (see below)

1.Insulation cylinder 2.Upper bracket 3.Upper outlet seat

4.Vacuum interrupter chamber 5.Flexible connection 6.Lower bracket

7. Lower outlet seat 8.Disc spring 9.Insulation pull rod

10.Drive arm 11.Circuit breaker shell 12.Split pull spring

13.Connection plate 14.Spindle 15.Over travel adjustment piece

16.External yoke 17.Closing and Opening Coil 18.Dynamic Core

19.Output Shaft 20.Manual Breaking Device

4.1 ZN85-40.5 type indoor vacuum circuit breaker main structure characteristics:

4.1.1. Vacuum interrupter chamber----the main body of the circuit breaker is mounted on the front of the circuit breaker frame and connected to the permanent magnetic actuator mechanism as a whole.

4.1.2. circuit breaker in closing is the main circuit current path.

4.1.3. Closing buffer device.

4.1.4. Permanent magnetic actuator.

4.1.5. Motorised closing operation.

4.1.6. Motorised opening operation.

4.1.7. Manual closing operation: (no main circuit energisation allowed).

4.1.8. Manual breaking operation.

4.1.9. Anti-fault interlocking.

4.2 . Vacuum interrupter working principle:

4.2.1 Vacuum is sealed in a vacuum pair of contacts to achieve the power circuit connection and disconnection, is the use of vacuum as an insulating medium. When it breaks a certain amount of current, moving and static contacts in the separation, the contacts will burn between the vacuum arc, with the increase in contact opening distance, the arc current over zero, the contact gap in the medium quickly from the conductor into an insulator, so the current is broken, the end of breaking.

4.2.2. After the circuit breaker closing operation is completed, the position of the auxiliary switch is switched to disconnect the closing circuit. It is not possible to perform a second closing operation on the circuit breaker while it is not tripped.

4.2.3. When the handcart-type circuit breaker has not reached the test position, the position switch contact in the chassis vehicle is not closed, and it is not possible to perform a closing operation on the circuit breaker.

4.2.4. After the handcart-type circuit breaker is closed in the test position or working position, the main shaft of the circuit breaker's inflection arm presses down on the interlocking bending plate of the chassis car, so that the interlocking bending plate withholds the rocking-in screw, and the handcart will not be able to move, preventing from advancing or pulling out of the loading area under the closed state.

Fixed type and removable type internal electrical schematic diagrams:

|

Symbol |

Name Function |

Name Function |

|

HC\FC |

Closing and closing contactors |

Control of Closing and Opening |

|

SA |

Auxiliary switch |

Switching circuits |

|

XT |

Secondary plug-in |

Control line summary |

|

YC |

Solenoid Coil |

Control Closing and Opening |

|

S8,59 |

Chassis vehicle auxiliary switch |

Position switches |

|

R |

Resistors |

Shunt current limiting |

ZN85-40.5 type indoor vacuum circuit breaker installation.

6.1 When the circuit breaker is lifted from the packing box, the hook should be hung at the clearly marked lifting hole on the circuit breaker, the upper and lower outlet arms should not be stressed when moving, and the circuit breaker should not be subjected to large shock vibration. Note: Before formal installation and operation, please remove the lifting device as required.

6.2 The circuit breaker has undergone strict factory inspection before leaving the factory, and the parameters are in accordance with the technical requirements. The following preparations should be made before formal installation:

6.3 Check the circuit breaker for damage, vacuum interrupter chamber for rupture, air leakage and loose screws;

6.4 Check whether the product nameplate and certificate of conformity are consistent with the order form, and whether the packing list is consistent with the real thing;

6.5 Remove surface dust and dirt, especially the insulation surface;

6.6 manually close and open the circuit breaker 5 times, check whether the position of the breaker closing and opening is normal;

6.7 Close and separate the circuit breaker electrically for 5 times, and check whether the closing and breaking position of the circuit breaker is normal;

6.8 Referring to the parameters on the certificate of conformity, check whether the contact opening distance and over-travel of the circuit breaker meet the requirements;

6.9 Handcart type circuit breaker is operated according to the following steps:

Insert the rocking-in handle into the rocking-in hole, rocking clockwise for advancing, counterclockwise rocking for launching. Advance the total stroke of about 200 mm. in the tripping state, should be smooth into the test position or working position, please shake the handle at medium speed for about 20 turns, when you hear the "ta" sound that is in place (do not use excessive force and damage to the rocking mechanism).

OEM/ODM Services:

At Shaanxi Yuguang Electric Co., Ltd., we understand the importance of customization. That's why we offer comprehensive OEM and ODM services to meet your specific requirements. Whether you need private labeling or custom product development, our experienced team is here to assist you every step of the way.

Certificates:

We take pride in our commitment to quality and safety. Our products are certified to meet the highest industry standards, including:

3C Certification

ISO 9001 Certification

21 Utility Model Patents and Design Patents

Why Choose Us:

State-of-the-art Manufacturing Equipment

Extensive Testing Facilities

Comprehensive Quality Assurance Processes

ISO 9001 Certified Quality Management System

One-year Warranty on All Products

Large Production Capacity

FAQ:

Q: What is the warranty period for your products? A: We offer a one-year warranty on all our products.

Q: Can you customize products according to our specifications? A: Yes, we provide OEM and ODM services to meet your specific requirements.

Q: Are your products compliant with international standards? A: Yes, our products meet all relevant international standards.

Q: What is the lead time for orders? A: The lead time depends on the quantity and customization requirements. Please contact us for more information.

Q: Do you provide technical support? A: Yes, we offer comprehensive technical support to our customers.

Packaging:

Wooden Box Packaging

Carton Packaging

Foam-filled Packaging

Waterproof and Moisture-proof Packaging

Customized Packaging

International Standard Packaging

Logistics:

Sea Freight

Air Freight

Land Transportation

Multimodal Transport

Express Delivery Services

Contact Us:

Ready to take your electrical projects to the next level? Contact us today at ygvcb@hotmail.com to discuss your requirements and explore partnership opportunities with Shaanxi Yuguang Electric Co., Ltd. Let's create a brighter future together.

Hot Tags: zn85-40.5 permanent magnet vacuum circuit breaker, China zn85-40.5 permanent magnet vacuum circuit breaker manufacturers, suppliers, factory, ZW32 Automatic Circuit Breaker, ZW17 40 5 Outdoor Vacuum Circuit Breaker, ZN23 40 5 Vacuum Circuit Breaker, ZN85 40 5 Vacuum Circuit Breaker, ZN63 24 Vacuum Circuit Breaker, ZW32 40 5 Outdoor Vacuum Circuit Breaker