ZW39-40.5 Outdoor Vacuum Circuit Breaker VCB

- Free Samples

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1. Overview

1.1 ZW39-40.5 outdoor high-voltage AC vacuum circuit breaker is suitable for AC rated frequency 50Hz, rated voltage 35kV power system, is the power system control and protection equipment. The circuit breaker can be operated frequently, and can be used in industrial and mining enterprises, power plants and substations for control and protection, and can be used as a contact circuit breaker.

1.2 The circuit breaker meets the requirements of GB 1984-2003 "High-voltage AC Circuit Breaker", GB/T 11022 "Common Technical Requirements for High-voltage Switch-gear and Control Equipment Standards" and JB/T 3855 "High-voltage AC Vacuum Circuit Breaker". Circuit breaker with vacuum as insulation and arc extinguishing medium, with CT10-A improved spring actuator, has a strong breaking capacity, small operating power, reliability and other characteristics.

1.3 Use of environmental conditions:

a) Ambient temperature: -40°C ~ +40°C.

b) Altitude: not more than 3000m;

c) Wind speed: not more than 34m/s;

d) Daily temperature difference: not more than 25°C.

e) Intensity of sunshine: not more than 0.Iw/m2;

f) Monthly average relative humidity: not more than 90%;

g) Seismic acceleration: not more than 0.2g horizontally and 0.1g vertically;

h) Thickness of ice cover: not more than 10mm;

i) The degree of air pollution does not exceed GB/T 5582 Ⅳ;

j) Installation: outdoor;

k) If the user has special requirements for the use of environmental conditions, please consult with the manufacturer.

The vacuum interrupter chamber, installing upward for the dynamic conductive rod of the vacuum interrupter chamber and connecting with the operating mechanism through the abductor's arm and insulated rod to complete the breaking and closing. It has a set of interlocking devices, which conveniently uses with the switch-gear. The interlocking device locks the vacuum circuit breaker at the closed position to prevent it from tripping due to the wrong pull of the trolley in the closed state. In an emergency, please operate the CS manual mechanism to keep the locking pin contacting latches to make the circuit breaker trips.

Main Technical Parameters

2.1 Main technical parameters of circuit breaker(see table 1 )

Table 1- Main technical parameters of circuit breaker

|

No. |

Items |

unit |

parameters |

|||

|

1 |

Rate Voltage |

kV |

40.5 |

|||

|

2 |

Rated frequency withstand voltage |

To ground |

kV |

95 |

||

|

Outlet |

95 |

|||||

|

3 |

Rated lightning impulse withstand voltage |

To ground |

kV |

185 |

||

|

Outlet |

185 |

|||||

|

4 |

Rate Current |

A |

2000 |

2500 |

||

|

5 |

Rated Short Circuit Breaking Current |

kA |

31.5 |

|||

|

6 |

Rated short-time withstand current |

kA |

31.5 |

|||

|

7 |

Rated Short Circuit Duration |

S |

4 |

|||

|

8 |

Rated Short-Circuit Closing Current (Peak) |

kA |

80 |

|||

|

9 |

Rated peak withstand current |

kA |

80 |

|||

|

10 |

Rated short-circuit breaking current breaking times |

次 |

30 |

|||

|

11 |

Rated single capacitor bank opening current |

A |

630 |

|||

|

12 |

Rated out-of-step breaking current |

kA |

8 |

|||

|

13 |

Hetero-phase ground fault breaking current |

kA |

27.4 |

|||

|

14 |

Rated sequence of operation |

0-0.3s-C0-180s-C0 |

||||

|

15 |

Mechanical life |

times |

10000 |

|||

|

16 |

Rated voltage of storage motor |

V |

DC220/AC220/DC110 |

|||

|

17 |

Rated operating voltage |

Split gate coil |

V |

DC220/DC110 |

||

|

Closing Coil |

V |

DC220/DC110 |

||||

|

18 |

Vacuum degree of vacuum interrupter |

Newly shipped interrupters |

Pa |

<1.33×10-3 |

||

|

Within 20 years storage period |

Pa |

<6.6×ta |

||||

|

19 |

Weight of circuit breaker |

kg |

750( without CT) 1000(internal CT) |

|||

|

20 |

Rated filling pressure (20°C) |

MPa |

0.02-0.06(without CT)/(external CT) |

|||

|

21 |

SF gas make-up alarm pressure(20℃) |

MPa |

0.15(internal CT) |

|||

|

22 |

SF gas moisture content |

≤250×10-6(internal CT) |

||||

|

23 |

Annual gas leakage rate |

≤0.5% |

||||

|

24 |

Climbing distance of outer insulation |

To ground |

mm |

≥1255 |

||

|

Outlet |

≥1255 |

|||||

2.2 Mechanical characteristics and mechanical parameters of circuit breakers are shown in Table 2

Table 2 Main mechanical characteristics and mechanical parameters

|

No. |

items |

unit |

parameters |

|

|

1 |

Contact opening distance |

mn |

a=0 |

|

|

2 |

Contact over-travel |

mn |

6±1 |

|

|

3 |

Allowable contact wear thickness |

mm |

3 |

|

|

4 |

Opening speed |

m/s |

2.0±0.3 |

|

|

5 |

Closing speed |

m/s |

0.8±0.2 |

|

|

6 |

Contact closing bounce time |

ms |

≤3 |

|

|

7 |

Three-phase switching asynchronism |

ms |

≤2 |

|

|

8 |

Three-phase closing non-simultaneity |

ms |

≤2 |

|

|

9 |

Closing time |

Rated and maximum operating voltage |

s |

≤0.12 |

|

Minimum operating voltage |

≤0.15 |

|||

|

10 |

Split time |

Rated and maximum operating voltage |

s |

≤0.05 |

|

Minimum operating voltage |

0.05~0.065 |

|||

|

11 |

Closing time |

s |

≤0.1,woring≥0.1 |

|

|

12 |

Arc ignition time |

s |

≤0.02 |

|

|

13 |

Opening time |

s |

≤0.07 |

|

|

14 |

Resistance of main electric circuit |

μΩ |

≤50(without CT,external CT) |

|

|

15 |

Centre distance between phases |

mm |

770±1 |

|

3 Product structure characteristics and arc extinguishing principle

3.1 Product structure features

3.1.1 This product is an outdoor high voltage AC vacuum circuit breaker with a pillar structure and consists of an upper and lower sleeve. The vacuum interrupter is installed in the upper casing. The middle contact of the circuit breaker adopts a watchband contact, so that the product has a small circuit resistance and good conductivity and conductivity. The lower casing is a pillar, and there is an insulating tie rod in the casing to ensure that the live part is insulated from the ground. The three poles are connected to the centrally-arranged mechanism by means of a crank arm and an interphase connecting rod. When the mechanism is operated by splitting and closing, the transmission part (i.e. the crank arm, connecting rod, contact spring device, insulated tie rod, etc.) is transferred to the moving contact in the vacuum interrupter. Make the vacuum interrupter reliably break the load current and short circuit current while ensuring the mechanical characteristics of Table 2. The three poles are mounted on a common chassis.

3.1.2 The casing is filled with 0.02MPa ~0.06MPa (with or without CT) / 0.20MPa ~ 0.30MPa (with CT) SF. Gas (20℃), its role is to strengthen the insulation strength of the surface of the casing and the CT in the insulation part and to avoid the phenomenon of internal moisture condensation and moisture absorption when the temperature changes.

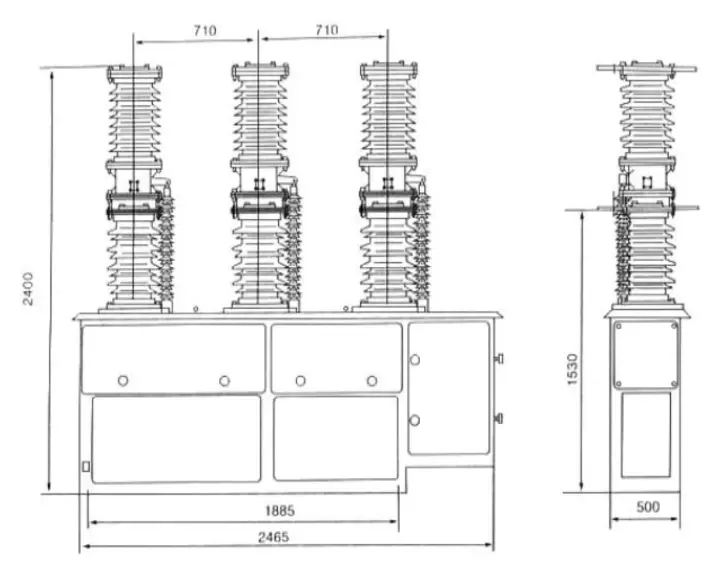

3.1.3 This product is not equipped with a transformer (see Figure 1a), internal current transformer (see Figure 1b), or external independent outdoor cast current transformer (see figure le) for measurement and protection. 3.1.4 If the cut-off value is small, the contact material of the vacuum interrupter is optimized. The average cut-off value is below 4A.

3.1.5 Strong breaking ability, long electrical life, rated short circuit breaking current up to 30 times.

3.1.6 High insulation level, the high vacuum degree of the vacuum interrupter makes it at a small opening distance, the power frequency withstand voltage of the fracture reaches 118kv, and the insulation between phases and the earth reaches 95 kV.

3.1.7 External creepage distance >31mm/kV, suitable for harsh environmental conditions.

3.1.8 CT10-A improved spring operating mechanism for circuit breakers adopts three-splint structure with good stability and mechanical life of more than 10,000 times.

2 Arc extinguishing principle The circuit breaker is installed with ceramic shell, exposed stainless steel shield cylinder structure, contact material is CuCr50, and cup-shaped longitudinal magnetic field vacuum arc extinguishing chamber. When the mechanism receives the tripping signal, under the action of the tripping spring, the dynamic contacts of the vacuum arc interrupter move downward. When the 6mm over-range is completed, the dynamic and static contacts begin to separate, and an arc is generated between the contacts. Under the action of the longitudinal magnetic field, the arc moves rapidly along the tangential direction of the surface of the contacts and spreads evenly to avoid arc aggregation. When the current passes zero, the arc is extinguished naturally. At the same time, the longitudinal magnetic field can maintain a low arc voltage, know the arc energy and know the electric corrosion rate, so that the arc burns the contact lightest, and the breaking ability and electric life are improved.

4 CT10-A improved spring operating mechanism

4.1 Introduction to CT10-A improved spring operating mechanism

4.1.1 CT10-A improved spring operating mechanism adopts a three-splint structure, and the energy storage driving part of the mechanism is arranged between the left and middle splint, completely isolated from the cam-four connecting rod part of the closing drive and the closing electromagnet, and does not affect each other. The part of the cam-four connecting rod is arranged between the middle and right plates, and the structure of double fan plate and double connected plate is adopted, which makes the force of each rotating shaft and roller reasonable, uniform, small wear and good stability.

4.1.2 The energy storage methods of CT10-A improved spring operating mechanism include motor energy storage and human energy storage. The opening and closing operation has electromagnet operation and manual button operation.

4.1.3 Auxiliary switch: Choose F9-201/W (L) type, a total of 10 pairs of normally open contacts, 10 pairs of normally closed contacts, contacts allow long-term passing current of not less than 10A and have a fast action structure.

4.1.4 Travel switch: Choose LX-44CSKZ-22, a total of 2, 8 contact points. Among them, 3 pairs of contacts are standby, and the other 5 pairs of contacts are connected in the secondary circuit, and the continuous current that the contacts can pass is DC 3A, and it is equipped with an arc blowing device.

4.1.5 Energy storage motor: HDZ type AC and DC dual-purpose single-phase series motor is adopted, and its main technical parameters are shown in Table 3:

Table 3 Main technical parameters of electric motor

|

Motor Model |

HDZ26005B |

|

|

Rated working voltage(V) |

DC/AC220 |

DC110 |

|

Rated power(W)/speed(r/min) |

600/530 |

|

|

Energy storage time under rated voltage(s) |

≤8 |

|

|

Normal working voltage range |

85%~110% of rated operating voltage |

|

4. 1. 6 Manual energy storage: 350mm long energy storage handle, the maximum operating force is less than 520N.

4.1.7 Minute and closing electromagnet: solenoid electromagnet is used, and its main technical parameters are shown in Table 4.

Table 4 Main technical parameters of solenoid

|

Rated working voltage(V) |

DC220 |

DC110 |

|

Rated operating current of interrupter country(A) |

1.6 |

3.4 |

|

Resistance of coil at 20℃(Ω) |

137 |

32 |

|

Rated operating current of closing coil(A) |

1.8 |

2.4 |

|

Resistance of closing coil at 20℃(Q) |

120 |

46 |

|

Normal Working Voltage Range |

Closing 85%~110%, opening 65%~120% of the rated working voltage |

|

Typically steps we should adopt when we use the ZW39-40.5 vacuum circuit breaker

Typically steps we should adopt for the ZW39-40.5 vacuum circuit breaker using are below:

Determine your requirements:

Identify your specific electrical power system requirements, including the rated voltage, rated current, breaking capacity, and a few poles needed for your application. Ensure that the ZW39-40.5 model meets your system's specifications.

Consult with Shaanxi Yuguang Electric Co.,Ltd to offer the ZW39-40.5 vacuum circuit breaker. You can search online or consult electrical equipment distributors to find suitable options.

Provide project details:

Share relevant information about your project with the supplier or manufacturer, including application, the required quantity of circuit breakers, technical specifications, and any specific customization requirements.

Request a quotation:

Ask for a quotation for the ZW39-40.5 vacuum circuit breaker according to project requirements. The supplier or manufacturer will offer you the formal quotation list, lead times, and additional terms and conditions.

Evaluate the quotation:

Carefully review the quotation list, considering price, delivery, warranty, and after-sales service. Compare multiple quotations if necessary to make an informed decision.

Place an order:

If you are satisfied with the quotation, draft the contract with the chosen supplier or manufacturer. They will guide you through their specific ordering process, which may involve signing a purchase agreement and providing necessary payment and shipping details.

Follow up and coordinate delivery:

Maintain communication with the supplier or manufacturer to ensure a smooth delivery process. Confirm the delivery schedule, shipping method, and any necessary documentation required for customs clearance.

Installation and commissioning:

Once you receive the ZW39-40.5 vacuum circuit breaker, engage qualified electrical professionals to install and commission the circuit breaker by relevant safety guidelines and regulations.

We usually supply professional installation for customers so that they operate successfully.

OEM/ODM Services:

At Shaanxi Yuguang Electric Co., Ltd., we understand the importance of customization. That's why we offer comprehensive OEM and ODM services to meet your specific requirements. Whether you need private labeling or custom product development, our experienced team is here to assist you every step of the way.

Certificates:

We take pride in our commitment to quality and safety. Our products are certified to meet the highest industry standards, including:

3C Certification

ISO 9001 Certification

21 Utility Model Patents and Design Patents

Send Inquiry

You may like